Learn How to Improve Sandblasting Efficiency

Learn How to Improve Sandblasting Efficiency

Most people may not know that sandblasting requires a lot of time. For the same surface, sandblasting takes twice as long as painting. The reason for the difference is their different processes. Painting is more flexible in operation. You can control the amount of paint at will. However, the blasting work is affected by the blasting pattern, size, and air velocity of the nozzle, which affects its efficiency. This article will analyze how to improve the efficiency of sandblasting from diverse aspects to spend less time to achieve the best effect.

Tip 1 Please don’t put too much abrasive into the air stream

It is one of the most common misconceptions. Some operators believe that adding more abrasive particles means more production. However, it is wrong. If you put too much medium into the airflow, the speed of it will slow down, reducing the impact force of the abrasives.

Tip 2 Select the appropriate compressor, sandblast nozzle size, and type

The sandblasting nozzle is connected with the compressor. The larger the nozzle, the larger the compressor size required for sandblasting. The nozzle is one of the vital points affecting sandblasting efficiency.

Venturi nozzles create a wide blast pattern, which is more suitable for working on a large area of the surface. Straight bore nozzles create a tight blast pattern, suitable for small areas. For the same type of nozzle, the smaller the orifice of the nozzle, the greater the force impacting on the surface.

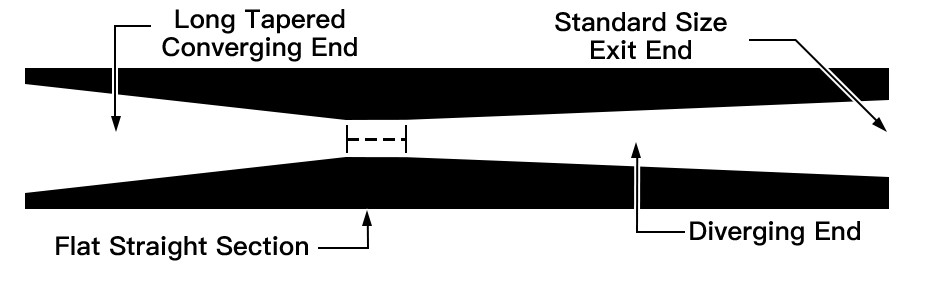

Structure of Venturi Nozzle:

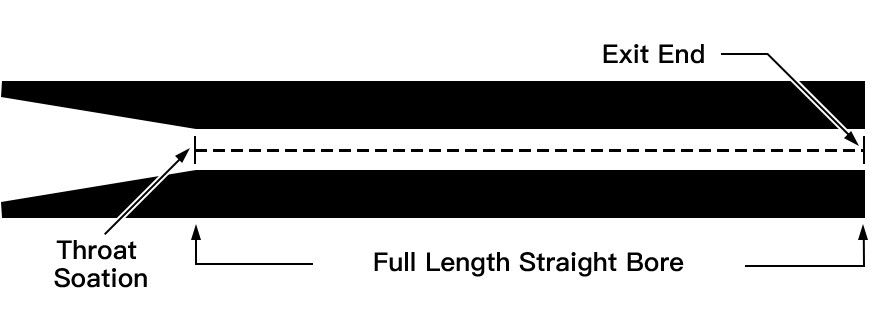

Structure of Straight Bore Nozzle:

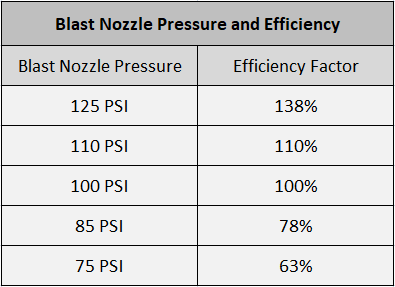

Tip 3 Choose the most blast pressure that meets your surface profile needs

Your sandblasting pressure will affect the impact speed and the depth of abrasive. Select the appropriate blast pressure according to your application. For example, if you just want to remove the coating without changing the substrate surface, you need to reduce your sandblasting pressure. When you acquire a safe sandblasting pressure range, please keep the pressure as high as possible during sandblasting to ensure maximum production. For the most pressure, it is recommended that you feed the sandblasting nozzle with a larger diameter hose. Because the larger the hose diameter, the smaller the pressure loss.

For an overview of the speed differences based on pressure, see the following table.

Tip 4 Make sure your sandblast pot has a large airline

Air pressure and volume are two main factors affecting sandblasting efficiency. A large airline can avoid pressure loss and improve efficiency. To achieve this goal, you should choose an intake pipe at least 4 times larger than the nozzle.

Tip 5 Sandblasting at an angle not perpendicular to the object surface

When you are sandblasting, the abrasives impact the surface and then reflect back from the surface. Therefore, sandblasting at a vertical angle will cause the medium from the nozzle to collide with the medium reflected from the surface, which reduces the impact speed and force of the abrasive. Therefore, we recommend that you blast at a slightly inclined angle.

Tip 6 Select the appropriate abrasive particles

According to your needs, choose the hardest medium among the abrasives you can select. Because the harder the abrasive, the faster it strips the surface and creates a deeper profile.

For more information of sandblasting and nozzles, welcome to visit www.cnbstec.com