Know Your Sandblast Nozzle Better

Know Your Sandblast Nozzle Better

Sandblast nozzle is a vital factor in the blasting process. Choosing a suitable nozzle that meets your application use helps you to complete your work efficiently and perfectly. You should comprehensively select the nozzle from the type, bore size, and liner material of the nozzle. In particular, the bore is very crucial because it affects whether you have enough CFM to create the pressure to complete the work. Only the nozzle type with good air pressure can better complete the work.

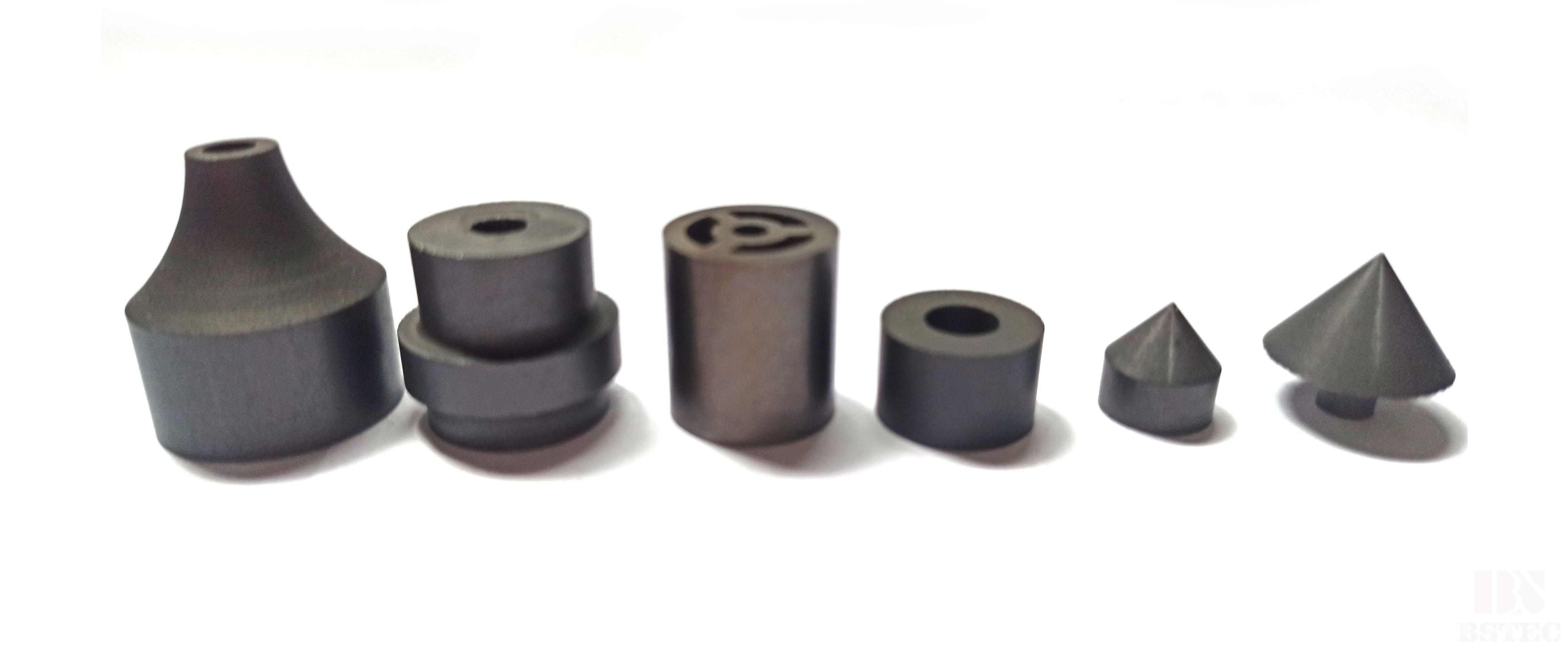

Nozzle Types

1. Long Venturi Nozzle

On a wide range of surfaces, you should use a long venturi nozzle that produces a wide blast pattern, which achieves 100% abrasive speed. The very long venturi nozzle, commonly called Bazooka nozzle, be used for real high pressure and large air and grit output. These are usually the first choice in construction projects such as bridge repainting.

2. Short Venturi Nozzle

The medium and small venturi nozzle has the same structure as the long venturi nozzle, and the abrasive speed is fast. These nozzles are usually used for cleaning small parts, such as the preparation of special coatings.

3. Straight Bore Nozzle

The straight bore nozzle creates a tight blasting pattern for spot blasting or blasting cabinet work. A straight bore nozzle is suitable for small work, such as part cleaning, weld shaping, handrail cleaning, step, grid cleaning, stone carving, etc.

4. Angled Nozzle

Angled sandblasting nozzles are becoming more and more popular for cleaning the interior of pipes or housing where other nozzles are hard to blast. Because most nozzles have the shape in straight that is difficult to blast areas that are narrow and inaccessible. Angled nozzles contain different angles, and there are even some types with reverse angles. You can choose the one that suits you best according to your needs.

Nozzle Materials

The material of the nozzle depends on the abrasive you choose to use, the frequency of blasting, the scale of work, and the rigors of the workplace.

The boron carbide nozzle with the best air pressure and abrasive provides a long service life. Boron carbide is an ideal choice for corrosive abrasives such as aluminum oxide. It is usually five to ten times more durable than tungsten carbide. Silicon carbide nozzle is similar to boron carbide nozzle, but its wear resistance is inferior to boron carbide, and the price is cheaper. Tungsten carbide nozzle provides long life and economy when rough handling is unavoidable.

Nozzle Thread

Diverse thread sizes are available for many different sandblasting machines. Coarse thread, also called 50 MM thread, is the construction thread that is a little bigger. The popular thread is 1-1/4 thread, also called the national male pipe thread. Some bigger sandblast nozzles apply to this thread. Thread 3/4 inch national male pipe thread is smaller and is used with 1/2 inch I.D. and 5/8 inch I.D. blast hose.

For more information of sandblasting and nozzles, welcome to visit www.cnbstec.com