Ithute ka Hare Pipe Blasting Nozzle ho tsoa ho Six Aspects

Ithute ka Hare Pipe Blasting Nozzle ho tsoa ho Six Aspects

Li-nozzles li ka sebelisoa hotse fapa-fapanengmefuta ya bokahodimo qetelo, eseng feela ka empa hapeka hare hobokahodimo, joalo ka phala. Tabeng ena, re lokela ho sebelisasesebelisoa,iNternal pipe blasting nozzle e nang le lisebelisoa tse fapaneng tse amanang,ho fihlela bokgopo ba rona bo batloang.

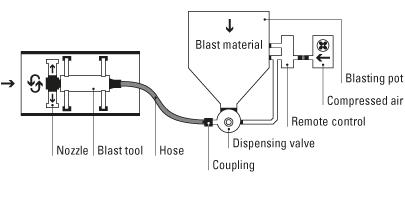

Molao-motheo

E le ts'ebetso ea ho phatloha ha lehlabathe tse ling, e kenyelletsa lintlha tse tharo tsa bohlokoa tsa ho phatloha ha lipeipi tse ka hare, compressor ea moea, lisebelisoa tsa ho phatloha, le molomo oa ka hare oa phaephe. Moea o qala ka ho sutumelletsoa ka ntle hore o nke likaroloana tsa makhopho ho tsoa pitseng ea lintho tse phatlohang. Ebe motsoako o phallela ho phala e ka hare e phatlollang nozzle ka hose e kopanyang. Qetellong, likaroloana tsa abrasive li fafatsoa ho hloekisa bokahare ba phala ho tloha ka boholo ba 19mm ho ea ho 900mm ka ntlha ea ho kheloha ea molomo. Ntlheng e hlahisa mokhoa oa ho phatloha ho etsa cone ho bolelang hore abrasive e hasane ka likhato tse 360, ho khothalletsa ho hloekisa ka katleho.

Sebopeho

Setaele se tloaelehileng, haholo-holo se arotsoe ka likarolo tse tharo tse kenyeletsang ntlha e khelohileng, 'mele oa nozzle, le coupling e kenyelletsang.mahoashe khoele kapa khoele e ntle. Bakeng sa setaele se seng se ikhethileng, hlooho e phatlohang e potolohang sebakeng sa ntlha e tloaelehileng ea ho kheloha ho thunya li-abrasives.

Thepa ea Liner

Lisebelisoa tsa liner li kenyelletsa mefuta e 'meli, Boron Carbide (B4C) le Tungsten Carbide (TC). B4C e na lee bobebe, mocheso o phahameng, ho tsofala, le ho hanyetsa ho bola. Ho thatafala ha eona ho latela daemane feela. TC e boetse e na le boima bo phahameng, ho hanyetsa ka theko e tlase haholo. Hangata, nyeoe e entsoe ka Aluminium.

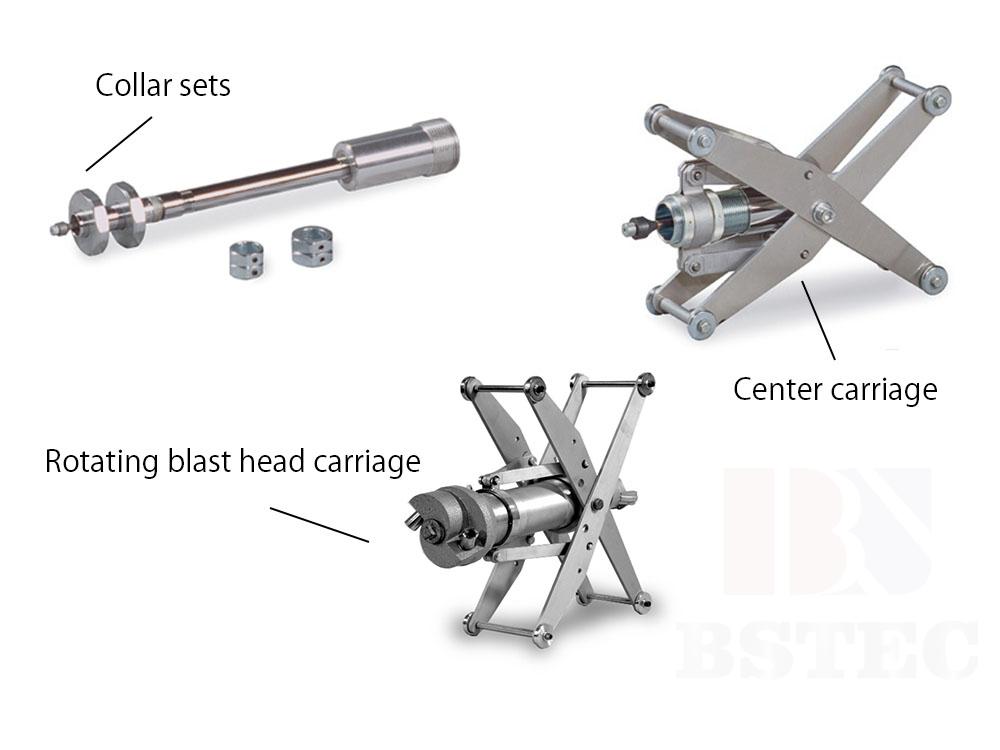

The Tools

Liphaephe tse fapaneng tse ka hare li hloka li-nozzles le lisebelisoa tse amanang le tsona.

19-50mm pipe ID: Bakeng sa bophara ba liphaephe tse ka hare ho tloha ho 19mm ho isa ho 50mm, mokhoa oa ho phatloha o hloka li-nozzles tsa setaele sa lerumo le li-collar sets bakeng sa ho fumana molomo ka har'a phala. Ho ea ka boholo bo fapaneng ba liphaephe, re hloka ho hlomella li-collar tse loketseng.

50-135mm pipe ID: Bakeng sa bophara ba liphaephe tse ka hare ho tloha ho 50 ho isa ho 135mm, e na le likhetho tse peli tsa lisebelisoa tsa ho qhomisa. E 'ngoe ke nozzle e nang le li-collar sets tse kholo (E kholo ka ho fetisisa e fumaneha bakeng sa 135 pipe I.D.). E 'ngoe ke nozzle e nang le kariki e bohareng e shebahalang joaloka sekere. Joalo ka ts'ebetso ea molala o behiloeng, koloi e bohareng ke ho eetsa hore molomo o tsamaye hantle phaepeng.

135-900mm pipe I.D.: Tabeng ena, e hloka li-nozzles tse nang le kariki ea hlooho e potolohang e nang le lihlooho tse 'maloa tse bilikang hore li thunye ka mokhoa o hlabang.(lisebelisoa tsa litšoantšo)

Ts'ebetso

Bakeng sa ho qeta holim'a phala ea ka hare, hangata e sebelisoa ho tlosa mafome, e leng se nolofalletsang mtsa botekgenikilikarolo ho ntlafatsa haholo.Ho qhomisa lehlabathe lathelerako le ka hare ke haholo-holo mokhoa oa ho fafatsa ka lebelo le phahameng ho latela molao-motheo oa khatello ea moea e le matla. Li-abrasives tse sebelisoang ha ho tlosoa mafome li na le mefuta e sa tšoaneng e kang lehlabathe la garnet, lehlabathe la quartz, morafo oa koporo, joalo-joalo.

Step1: Pele ho lehlabathe, bokaholimo baphala e ka haree tla hloekisoa pele. Ho hloekisa holim'a metsi ho bohlokoa hobane ho ama ka ho toba ho khomarela seaparo sohle.

Step2: Ho pepesehela letsatsi ho thusa ho liehisa bophelo ba tšebeletso ea ho roala. Ho phaella moo, ho na le mekhoa e meng joalo kaho hloekisa solvent,asitipickling.

Step3: Lokisetsa konpresser ea moea, ebe u hokahanya nozzle le bokaholimo bo lokelang ho phekoloa, 'me u boloke sebaka se ka bang 15 ~ 30 cm.. Re ka sebelisa lisebelisoa tse loketseng tsa ho phatloha ho fumana li-nozzles ka har'a liphaephe tse tsamaeang hantle.

Mohato oa 4: Sandblasting e na le phello le phello e sehangka harethephala, le bokaholimo bo kafihlabohloeki bo itseng le mahoashe a fapaneng.

Tlhokomeliso

1. Nakong ea ho hahoa ha sandblasting, tšireletso ea tšireletso ea bothoaperee tla apesoa ho qoba kotsi 'meleng.

2. Nakong ea kaho, e lokela ho boloka bonyane batho ba babeli ho qoba boemo ba tšohanyetso bo ka khonang’t sebetsana le motho a le mong.

3. Pele o sebelisa compressor ea moea, phala ea moea le mochini oa sandblasting li hloka ho hlahlojoa bakeng sa ho tiisa.

4. Khatello ea moea ea compressor ea moeaka moo ho ka khonehang’tfeta 0.8MPa, 'me valve ea moea e hloka ho buloa butle ha ho sebelisoa compressor ea moea.