Ha u tsebe ho khetha nozzle ea blast? Ho latela mehato e mene, ho bonolo!

Ha u tsebe ho khetha nozzle ea blast? Ho latela mehato e mene, ho bonolo!

--Mehato e mene e u bolella mokhoa oa ho khetha li-nozzles tse loketseng

Li-nozzles tsa lehlabathe li entsoe ka mefuta e fapaneng ka boholo le libopeho tse fapaneng ho tsoa ho lisebelisoa tse fapaneng. Ho khetha nozzle e nepahetseng ea sandblast bakeng sa ts'ebeliso e 'ngoe le e' ngoe ke taba ea ho utloisisa mefuta e fapaneng e amang ts'ebetso ea ho hloekisa le litšenyehelo tsa mosebetsi. Haeba ha u tsebe ho ikhethela nozzle e loketseng, latela mehato e 4 joalo ka tlase.

1. Khetha boholo ba Nozzle Bore

Ha u khetha nozzle, e qala ka ea haukonpresser ea moea. Ha u se u utloisisa hore na boholo ba compressor ea hau bo ama bokhoni ba tlhahiso joang, u tla batla ho shebaboholo ba nozzle. Khetha nozzle e nang le bore e nyane haholo 'me u tla be u siea matla a ho phatloha tafoleng. E kholo haholo 'me u tla hloka khatello ea ho phatloha ka mokhoa o atlehileng.

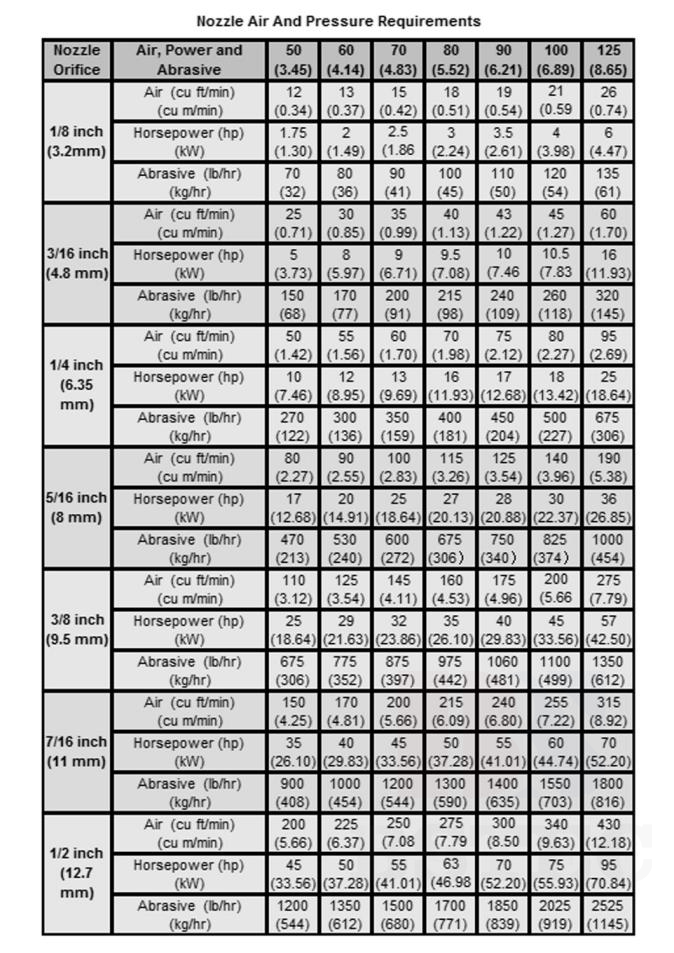

Tafole e ka tlase e bonts'a kamano lipakeng tsa bophahamo ba moea, boholo ba nozzle, le khatello ea molomo oa molomo 'me hangata e sebelisoa indastering ho khetha boholo ba molomo. Molemo oa eona oa 'nete ke ho khetha boholo bo nepahetseng ba nozzle bakeng sa khatello ea molomo e hlokahalang ho etsa mosebetsi.

2. Khetha Sebopeho sa Nozzle

E latelang kesebopeho sa molomo. Li-nozzles li na le libopeho tse peli tsa mantlha:Straight boreleVenturi, ka mefuta e mengata ea li-nozzles tsa Venturi.

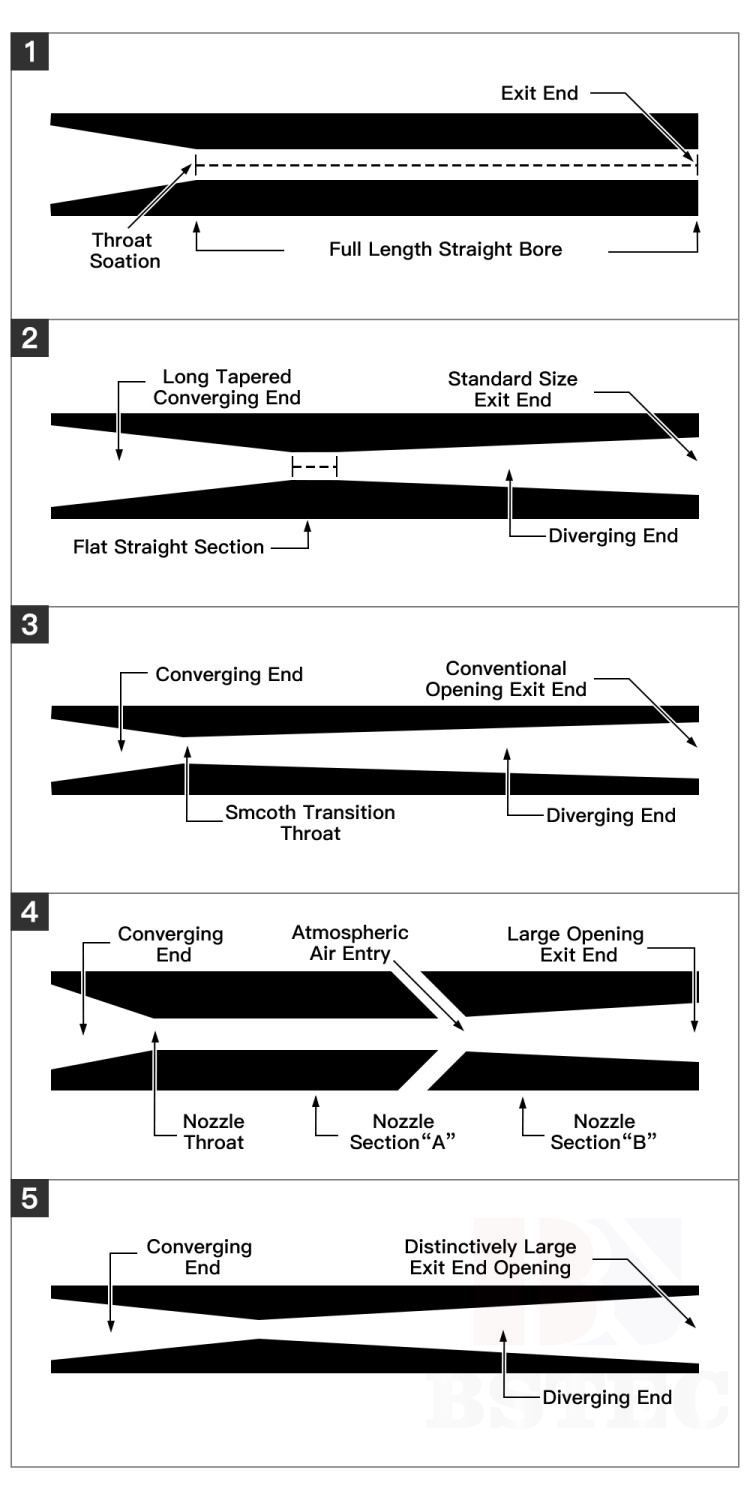

Li-nozzles tse otlolohileng tsa Bore(Nomoro ea 1) theha mokhoa o thata oa ho phatloha bakeng sa ho phatloha ha sebaka kapa mosebetsi oa khabinete ea ho phatloha. Tsena li molemo ka ho fetisisa bakeng sa mesebetsi e menyenyane e kang ho hloekisa likarolo, ho etsa seam seam, ho hloekisa li-handrails, litepisi, li-grillwork, kapa majoe a betliloeng le lisebelisoa tse ling.

Venturi e ne e e-na le li-nozzles(Nomoro 2 le 3) theha mokhoa o pharaletseng oa ho phatloha le ho eketsa lebelo la abrasive ka hoo e ka bang 100% bakeng sa khatello e fanoeng.

Li-nozzles tsa Venturi ke khetho e ntle ka ho fetisisa bakeng sa tlhahiso e kholo ha ho phatloha libaka tse kholoanyane. Li-nozzle tse peli tsa venturi le 'metso o sephara ke mefuta e ntlafalitsoeng ea molomo o molelele oa venturi.

Thehabeli venturisetaele (Nomoro ea 4) e ka nkoa e le li-nozzle tse peli tse latellanang tse nang le lekhalo le masoba lipakeng ho lumella ho kenngoa ha moea karolong e ka tlaase ea noka ea molomo. Qetello ea ho tsoa e boetse e pharaletse ho feta nozzle e tloaelehileng. Liphetoho ka bobeli li etsoa ho eketsa boholo ba mokhoa oa ho phatloha le ho fokotsa tahlehelo ea lebelo la abrasive.

Memetso e pharaletseng(Nomoro 5) e na le 'metso o moholo oa ho kena le mokoti o moholo oa ho tsoa. Ha li tsamaisana le hose ea boholo bo lekanang li ka fana ka keketseho ea 15% ea tlhahiso holim'a li-nozzles tse nang le 'metso o monyenyane. Hape ke mohopolo o motle ho ba le li-nozzles tse fumanehang bakeng sa matheba a thata joalo ka lattice ea monyaluoa, ka mor'a li-flanges, kapa liphaephe tse ka hare. Basebelisi ba bangata ba senya li-abrasives le nako ba emetse ricochet ho etsa mosebetsi. Nako e nyane e nkang ho fetohela hoangle nozzlee lula e hlaphoheloa kapele, 'me nako eohle ea mosebetsi e fokotsehile.

3. Khetha Thepa ea Nozzle

Ha u se u entse qeto ea boholo ba nozzle le sebōpeho, u tla batla ho nahana kathepalesela la nozzle le entsoe ka. Lintlha tse tharo tsa mantlha mabapi le ho khetha thepa e ntle ea nozzle ke ho tšoarella, ho hanyetsa tšusumetso, le theko.

Khetho ea thepa ea nozzle e ipapisitse le hore na u khetha eng, hore na u phatloha hangata hakae, boholo ba mosebetsi le maemo a thata a sebaka sa mosebetsi. Mona ke litataiso tse akaretsang tsa ts'ebeliso ea lisebelisoa tse fapaneng.

Tungsten carbide nozzles:Ka fana ka bophelo bo bolelele le moruo ha ho sebetsana ka thata ho ke ke ha qojoa. E loketse ho phatloha ha slag, likhalase, le li-mineral abrasives.

Silicon carbidenozzles:Ha e na tšusumetso ebile e tšoarella joalo ka tungsten carbide, empa ke karolo ea boraro feela ea boima ba li-nozzles tsa tungsten carbide. Khetho e ntle haholo ha basebetsi ba le mosebetsing nako e telele 'me ba khetha nozzle e bobebe.

Boron carbide nozzles:E thata haholo ebile e tšoarella, empa e brittle. Boron carbide e loketse bakeng sa li-abrasives tse mabifi tse kang aluminium oxide le lihlopha tse khethiloeng tsa liminerale ha ho sebetsana ka thata ho ka qojoa. Boron carbide hangata e tla apesa tungsten carbide ka makhetlo a mahlano ho isa ho a leshome le silicon carbide makhetlo a mabeli ho isa ho a mararo ha ho sebelisoa li-abrasives tse mabifi. Theko e boetse ke eona e phahameng ka ho fetisisa har'a bona.

4. Khetha Khoele le Jacket

Qetellong, o hloka ho khetha thepa ea baki e sireletsang bore. Hape u lokela ho nahana hore na ke mofuta ofe oa khoele o loketseng litlhoko tsa hau tsa ho qhomisa lehlabathe: khoele e mahoashe kapa khoele e mahoashe.

1) Jacket ea Nozzle

Jacket ea Aluminium:Li-jackets tsa aluminium li fana ka ts'ireletso e phahameng haholo khahlanong le ts'enyo ea tšusumetso ho bobebe.

Jacket ea tšepe:Li-jackets tsa tšepe li fana ka ts'ireletso e phahameng haholo khahlanong le tšenyo ea tšusumetso ho boima bo boima.

Jacket ea Rabara:Baki ea rabara e bobebe ha e ntse e fana ka tšireletso ea tšusumetso.

2) Mofuta oa khoele

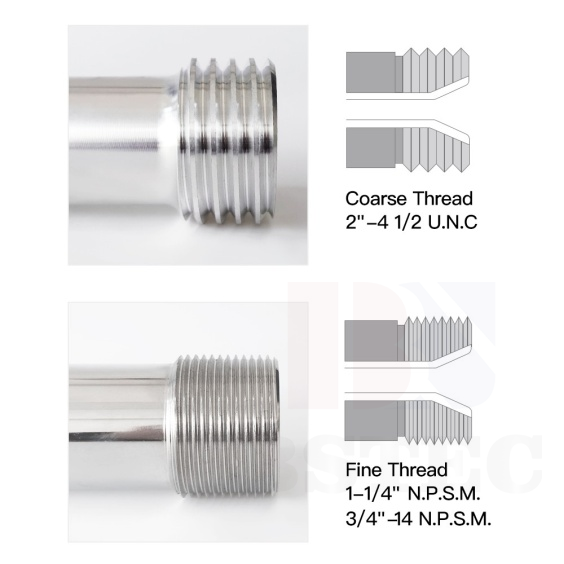

Mahoashe (Mokonteraka) Khoele

Khoele e tloaelehileng ea indasteri ho likhoele tse 4½ ka inch (TPI) (114mm), setaele sena se fokotsa haholo monyetla oa ho tšela likhoele 'me ho bonolo haholo ho e kenya.

Khoele e Ntle(Khoele ea NPSM)

The National Standard Free-Fitting Straight Mechanical Pipe Thread (NPSM) ke khoele e otlolohileng ea Indasteri e sebelisoang haholo Amerika Leboea.

LIEKETSENG QETELA

Moea o moholo le li-nozzles tse kholo li lebisa ho litekanyetso tse kholo tsa tlhahiso, empa ke sebōpeho sa sebono sa molomo se laolang ho potlakisa ha likaroloana le boholo ba mokhoa oa ho phatloha.

Ka kakaretso, ha ho na nozzle e ntle ka ho fetisisa, ntlha ea bohlokoa ke ho fumana li-nozzles tse loketseng ka ho fetisisa bakeng sa tšebeliso ea hau.