Na u hlile u tseba blast venturi nozzle? A re e hlahlobeng!

Na u hlile u tseba blast venturi nozzle? A re e hlahlobeng!

--Utloisisa venturi nozzle ho tsoa likarolong tse tharo

Abrasive Blasting, e le mokhoa oa ho qeta bokaholimo oo ka kakaretso o kenyelletsang ts'ebeliso ea mochini o hatellang moea le mochini o qhomisang, ke ho fafatsa likaroloana tse hohlang sebakeng se hlokahalang hore se be boreleli kapa se be mahoashe.

Nozzle, e le ntho ea bohlokoa ea ho qhomisa, e tsoetse pele ho latela litlhoko tsa linako. Ho ne ho e-na le li-nozzles tse otlolohileng feela bohareng ba bo-1950. Leha ho le joalo, motho ea neng a li qhomisa o ile a fumana bothata ba tsona ka lebaka la ho tsofala le ho hoholeha ka hare. 'Me ka nako eo, mokhoa o sebetsang hantle oa ho phatloha, venturi nozzle, o hlahile. Joale li-nozzles tsa venturi ke eng? A re e shebeng ka botlalo.

Sebopeho sa Venturi Nozzle

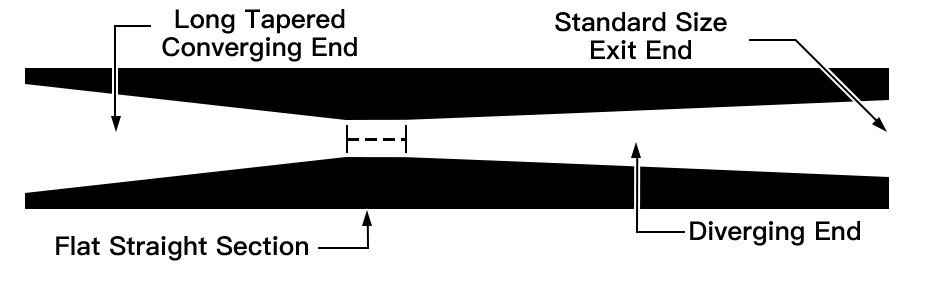

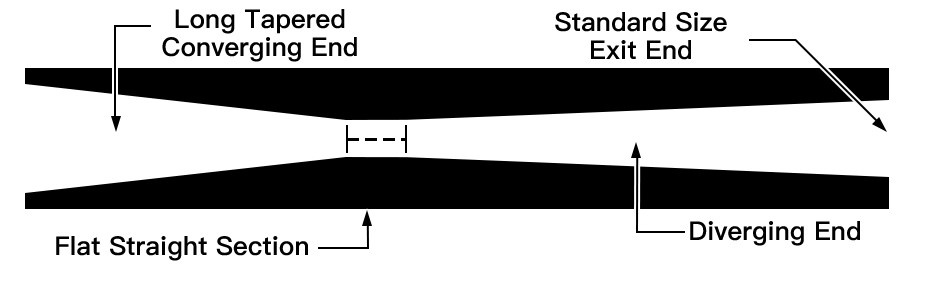

Mabapi le ponahalo, venturi nozzle e arotsoe likarolo tse tharo. Ntlha ea pele, e qala ka sebaka se selelele se pota-potiloeng se pota-potiloeng, se lateloa ke karolo e khutšoanyane e otlolohileng e bataletseng, ebe e na le qetello e telele e khelohang e fetohang e pharaletseng ha e fihla haufi le molomo oa molomo. Moqapi o joalo o thusa ho eketsa katleho ea mosebetsi ka 70%, hona see se finyelloa joang?

Moea le abrasive li kena ka sekoting ka sekoting se selelele se kopanyang ebe se phallela karolong e khuts'oane e otlolohileng ha khatello e fokotseha ka nako eo, e leng se bakang phapang ea khatello lipakeng tsa kahare le kantle. Phapang ena ea khatello e fana ka matla a ka ntle bakeng sa likaroloana tsa abrasive. Ha abrasive e tloha molomong, lebelo le phahame habeli ho feta la nozzle e otlolohileng. Kahoo bokaholimo bo hloeka ka katleho.

Mefuta ea Venturi Nozzle

The venturi blasting nozzle e na le mekhahlelo e fapaneng e arotsoeng ho tloha mahlakoreng a fapaneng. Ka mohlala, ho ea ka pono ea ho kena, e arotsoe ka mokhoa o le mong oa ho kenya le ho kenya habeli. Ka kakaretso e arotsoe ka boron carbide, silicon carbide, le tungsten carbide ka thepa ea liner. Ho feta moo, mofuta oa khoele o arotsoe ka khoele e mahoashe le khoele e ntle.

1.Classified by inlet

1.1 Monko o le mong oa venturi

Nozzle ea venturi e le 'ngoe, e latela Venturi Effect e tloaelehileng, ho bolela hore e na le tsela e le 'ngoe feela ea ho hula moea le ho senya ho phalla karolong e otlolohileng e bataletseng.

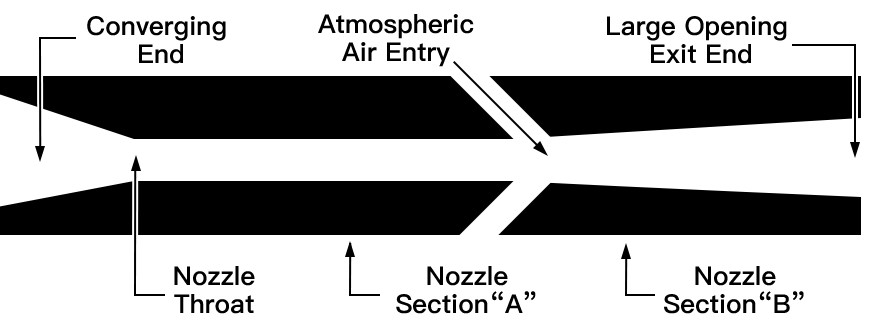

1.2 Nozzle ea venturi e kenang habeli

Joalokaha ho bontšitsoe setšoantšong se ka holimo, e na le li-nozzles tse peli tse amanang le lekhalo pakeng tsa tsona. Ho na le masoba a manyane a robeli ho potoloha lekhalo ho thusa ho hula moea o potolohileng molomo oa molomo, e leng se etsang hore moea o ntšitsoeng o be moholo ho feta moea o hatelitsoeng o huloang ka molomong, kahoo lebelo la ho senya lea ntlafala e lebisang tlhoekisong e sebetsang hantle haholoanyane.

2. E arotsoe ka lisebelisoa tsa liner

Lisebelisoa tse tharo tse tsebahalang haholo tse sebelisoang kajeno bakeng sa li-nozzles tse phatlohang ke boron carbide, silicon carbide, le tungsten carbide.

2.1 Boron carbide venturi nozzle

Boron carbide nozzle e na le boima bo phahameng, moaparo o motle haholo, le ho hanyetsa abrasion. Ho tloha ponahalong, ke leseli le fokolang le fokolang.

2.2 Silicon carbide venturi nozzle

Silicon carbide nozzle e na le litšobotsi tse tsitsitseng tsa lik'hemik'hale le ho hanyetsa ho apara hantle. Bokaholimo ba silicon carbide nozzle bo batla bo tšoana le boron carbide. Ha ho bapisoa ka hloko, silicon carbide e lefifi ka ho bonahatsa matla. Monyetla oa eona ke hore e khona ho bopeha habonolo ka libopeho tse fapaneng, 'me e na le theko e tlase, athe khanyetso ea ho roala ke 1/3 ho 1/2 ea li-nozzles tse hatellang tse chesang.

2.3 Tungsten carbide venturi nozzle

Tungsten carbide nozzle e na le boima bo phahameng, khanyetso e ntle ea ho apara, le sebopeho se tsitsitseng se hlokang tlhokomelo e nyane. Ke khetho e ncha bakeng sa li-blasting operators hobane e na le nako e telele ea nako e telele le ho apara ha u sebelisa abrasive e thata.

3. E arotsoe ka khoele

E ka aroloa hoo e batlang e le khoele e mahoashe le khoele e ntle.

3.1 Khoele e Mahoashe 2”-4 1/2 U.N.C.

Khoele e mahoashe e na le lekhalo le leholoanyane pakeng tsa khoele ka 'ngoe, ho bolelang hore e loketse haholoanyane