Zoyambira Kusankha Zigawo za Sandblasting

Zofunika Kusankha Zigawo za Sandblasting

Mchenga unali wonyezimira wofala kwambiri pochita izi, motero amatchedwa sandblasting. M'zaka 50 zapitazi, zida zowonjezera zasinthidwa kuti zigwiritsidwe ntchito poyeretsa.

Masiku ano, mawu akuti kuwomba kwapawayilesi ndi kuyeretsa kwamoto kumatanthawuza bwino momwe ntchitoyi ikuyendera, popeza zida zophulika zimatha kukhala ndi zinthu zingapo, monga malasha, garnet, mikanda yamagalasi, zipolopolo za mtedza, ndi chimanga.

Kuphulitsa kwa media kumatha kugwiritsidwa ntchito pafupifupi gawo lililonse la thirakitala, kutengera kusakanikirana koyenera kwa media media, kuthamanga kwa mpweya, voliyumu, ndi bomba lophulika.

Zotsatirazi ndi zina mwazofunikira posankha zigawo.

Compressor

Mpweya wa compressor ndiye chinthu chofunikira kwambiri pakupanga mchenga. Imapereka kuchuluka kwa mpweya ndi kukakamiza kusuntha zowulutsira zowononga ngakhale payipi ndi mphuno yophulika ndi liwiro lokwanira kuchotsa sikelo, dzimbiri, kapena zokutira zakale pamalo omwe mukufuna.

Pakuphulitsa nduna, 3 mpaka 5 cubic feet pa mphindi (cfm) ingakhale yokwanira, akutero. Kwa ntchito zazikulu, mitundu yosiyanasiyana ya 25 mpaka 250 cfm ingakhale yofunikira.

Posankha poto yophulika kapena kabati, pali mitundu iwiri yosankha: chakudya choyamwa ndi chokakamiza.

Feed Systems

Njira zoyamwitsa zimagwira ntchito poponyera ma abrasives mwachindunji mumfuti yophulika. Izi zimadalira mpweya wa compressor womwe umalowetsedwa mumfuti yophulika kuti apange vacuum. Mfuti ikayambika, abrasive imayamwa mumzere wa chakudya kupita ku mfuti yophulika. Mpweya umene ukutulukawo umanyamula chonyezimiracho n’kupita nacho pamalo amene wafuna.

Mosiyana ndi izi, makina odyetsera mphamvu amasunga chotupa mu chotengera kapena mphika. Mphika umagwira ntchito mothamanga mofanana ndi payipi yakuthupi. Vavu yoyang'anira yomwe ili pansi pa mphikayo imatengera chivundikirocho kukhala mtsinje wothamanga kwambiri. Mtsinje wa mpweya ndiye umanyamula abrasive kudzera pa hose yophulika kupita kumalo ogwirira ntchito.

The blast nozzle ndi chipangizo chomwe chimagwiritsidwa ntchito kukulitsa kuthamanga kwa mchenga wa abrasive. Ngakhale pali mitundu ingapo ya nozzles, pali inayi yodziwika.

* Mphuno yoboola yowongoka imapanga njira yothina yotsuka malo kapena kuphulitsa kabati. Nthawi zambiri amagwiritsidwa ntchito poyeretsa tizigawo tating'ono.

* Nozzle ya venturi ndiye chisankho chabwino kwambiri pakuyeretsa kwambiri pamalo akulu. Ndikofunika kuzindikira, komabe, kuti pophulika pazipani zambiri (100 psi kapena kuposerapo), ma abrasives amatha kufika pa liwiro la 500 mph.

* Mphuno yophulika ya venturi iwiri imatha kuganiziridwa ngati milomo iwiri yoyikidwa kumapeto mpaka kumapeto. Mabowo olowetsa mpweya m'thupi la mphuno amalola mpweya wa kompresa kusakanikirana ndi mpweya wa mumlengalenga. Kuchita kwa venturi uku kumawonjezera cfm ndikuwonjezeranso kukula kwa mawonekedwe ophulika. Deardorff akunena kuti nozzle ya venturi iwiri ndiye chisankho chabwino kwambiri choyeretsa chochepa. Izi zili choncho chifukwa kuyamwa kwa mabowo olowetsa mpweya amatha kunyamula ma abrasives olemera kwambiri, owundana kudzera papaipi yakuthupi pamagetsi otsika.

* Mphuno ya feni imapanga chifaniziro cha fan chomwe chimagwiritsidwa ntchito kuphulitsa malo akulu, athyathyathya. The fan nozzle imafuna kuchuluka kwa mpweya wa cfm kuti igwire ntchito.

Ma Nozzles amapezekanso ndi kusankha kwa zida zomangira, zomwe zimaphatikizapo aluminiyamu, tungsten carbide, silicon carbide, ndi boron carbide. Mwachibadwa, kusankha kumadalira bajeti yanu ndi zovuta za ntchitoyo. Ingokumbukirani kuti kugwiritsa ntchito media kumawonjezeka ndi kuvala kwa nozzle.

Zonse Zokhudza Abrasives

Zinthu zomwe zimakhudza ntchito ya abrasive ndi izi.

* Kulimba kwa zonyansa, dzimbiri, kapena zokutira zakale kuti zichotsedwe.

* Kupanga kwapamwamba komanso kukhudzika.

* Ubwino woyeretsa wofunikira.

* Mtundu wa abrasive.

* Mtengo ndi ndalama zotayira.

* Kuthekera kobwezeretsanso.

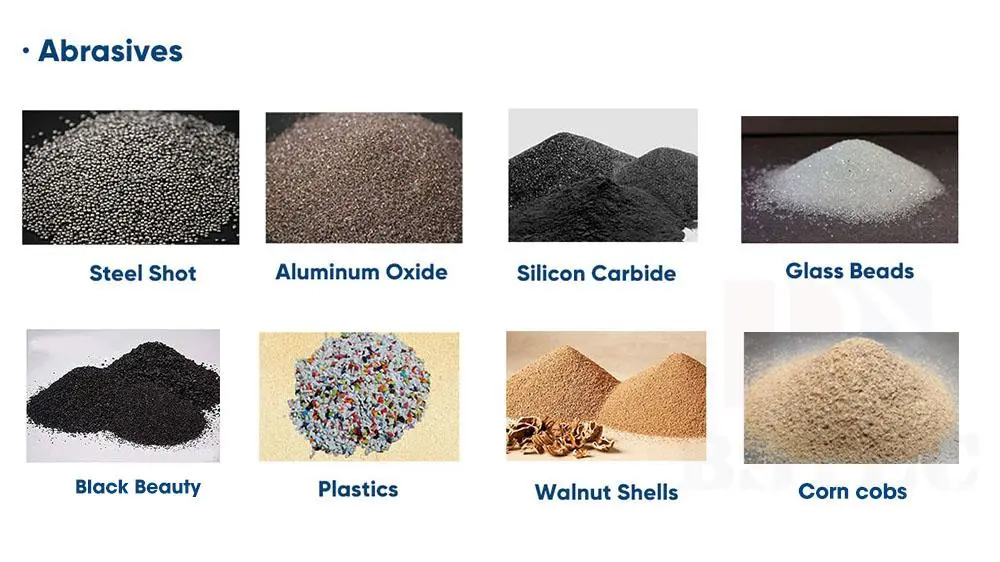

The abrasive ndi gawo la njira iliyonse yophulika yomwe imagwira ntchito yoyeretsa. Pali magulu anayi akuluakulu azinthu zowononga.

* Mafuta achilengedwe amaphatikiza mchenga wa silika, mchenga wamchere, garnet, ndi specular hematite. Izi zimatengedwa ngati abrasives otsika mtengo ndipo amagwiritsidwa ntchito makamaka pophulitsa panja.

* Zipangizo zopangidwa ndi anthu, monga mikanda yagalasi, aluminium oxide, silicon carbide, steel shot, ndi pulasitiki, zimatha kugwiritsidwanso ntchito ndipo zitha kugwiritsidwa ntchito m'makina omwe amalola kuchira ndikubwezeretsanso.

* Ma abrasives opangidwa ndi zinthu - monga slag ya malasha, omwe amapangidwa ndi magetsi opangidwa ndi malasha - amatengedwa kuti ndi omwe amagwiritsidwa ntchito kwambiri pambuyo pa mchenga wa silica.

* Ma abrasives osagwiritsa ntchito zitsulo nthawi zambiri amawaika ngati organic. Izi zimaphatikizapo mikanda yagalasi, pulasitiki, ndi mitundu ya tirigu monga chimanga, wowuma wa tirigu, zipolopolo za pecan, zipolopolo za kokonati, ndi zipolopolo za mtedza. Ma organic abrasives amagwiritsidwa ntchito ngati pakufunika kuwonongeka pang'ono pamwamba.

Mawonekedwe ndi Kuuma

Mfundo zina posankha abrasive ndi mawonekedwe a thupi ndi kuuma.

"Mawonekedwe a abrasive amatsimikizira mtundu ndi liwiro la kuphulika," akutero a Deardorff. "Ma abrasives aang'ono, akuthwa, kapena owoneka mosiyanasiyana amayeretsa mwachangu ndikuchotsa malo omwe mukufuna. Ma abrasives ozungulira kapena ozungulira amatsuka mbali zake popanda kuchotsa zotsalira zochulukirapo."

Kuuma, panthawiyi, kumakhudza osati liwiro lomwe limatsuka, komanso kuchuluka kwa fumbi lopangidwa ndi kuwonongeka kwachangu, komwe kumakhudzanso mwachindunji kuthekera kwa kubwezeretsanso.

Kuuma kwa abrasive kumagawidwa ndi chiwerengero cha Mohs - chiwerengero chapamwamba kuchokera ku 1 (talc) mpaka 10 (diamondi), ndizovuta kwambiri.

Ngati mukufuna za Abrasive Blast Nozzle ndipo mukufuna zambiri ndi zambiri, mutha KUTITANANI NAFE pa lamya kapena makalata kumanzere, kapena TITUMIZANI MAIL pansi pa tsamba.