Simukudziwa momwe mungasankhire phokoso lophulika? Potsatira njira zinayi, ndi zosavuta!

Simukudziwa momwe mungasankhire phokoso lophulika? Potsatira njira zinayi, ndi zosavuta!

--Masitepe anayi akukuuzani momwe mungasankhire ma nozzles oyenera

Mitsuko ya mchenga imapangidwa m'mitundu yosiyanasiyana ndi makulidwe ndi mawonekedwe osiyanasiyana kuchokera kuzinthu zosiyanasiyana. Kusankha sandblast nozzle yoyenera pa ntchito iliyonse ndi nkhani yongomvetsetsa zomwe zimakhudza kuyeretsa komanso mtengo wantchito. Ngati simukudziwa momwe mungasankhire nozzle yoyenera, tsatirani njira zinayi monga zilili pansipa.

1. Sankhani Kukula kwa Nozzle Bore

Posankha nozzle, imayamba ndi yanumpweya kompresa. Mukamvetsetsa momwe kukula kwa kompresa yanu kumakhudzira luso la kupanga, ndiye kuti mudzafuna kuyang'anakukula kwa nozzle. Sankhani mphuno yokhala ndi chobowola chaching'ono kwambiri ndipo mukhala mukusiya kuphulika kwina patebulo. Kuphulika kwakukulu kwambiri ndipo mudzasowa kukakamiza kuti muphulike bwino.

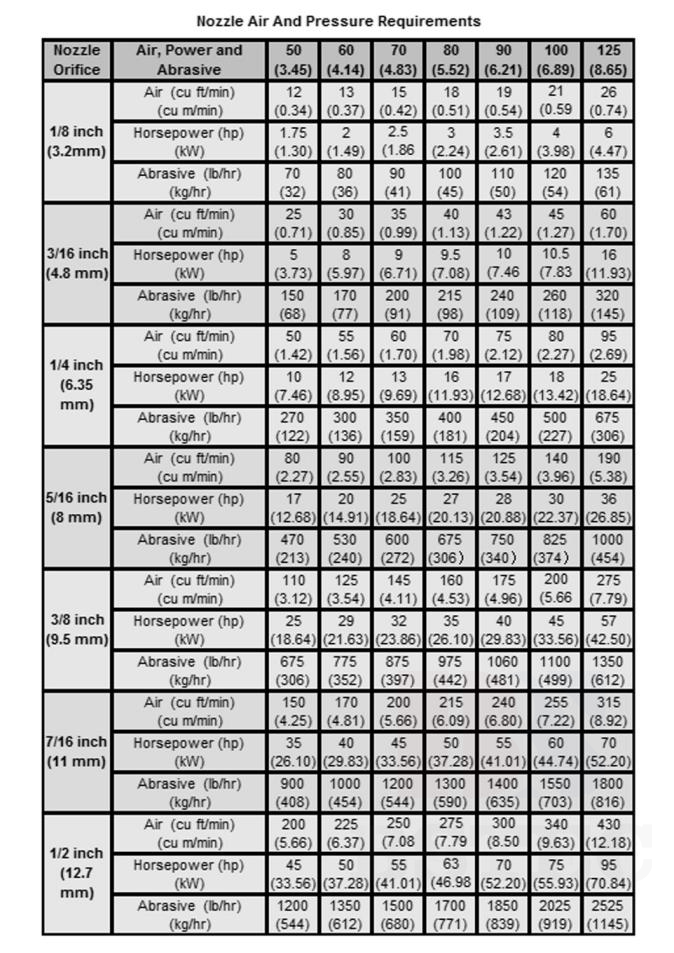

Gome ili pansipa likuwonetsa kulumikizana pakati pa kuchuluka kwa mpweya, kukula kwa nozzle, ndi kuthamanga kwa nozzle ndipo nthawi zambiri amagwiritsidwa ntchito posankha kukula kwa nozzle. Phindu lake lenileni ndikusankha kukula kokwanira kwa nozzle kuti mugwire ntchitoyo.

2. Sankhani Mawonekedwe a Nozzle

Chotsatira ndimawonekedwe a nozzle. Nozzles amabwera m'mawonekedwe awiri:Smtunda wautalindiVenturi, ndi mitundu ingapo ya ma nozzles a Venturi.

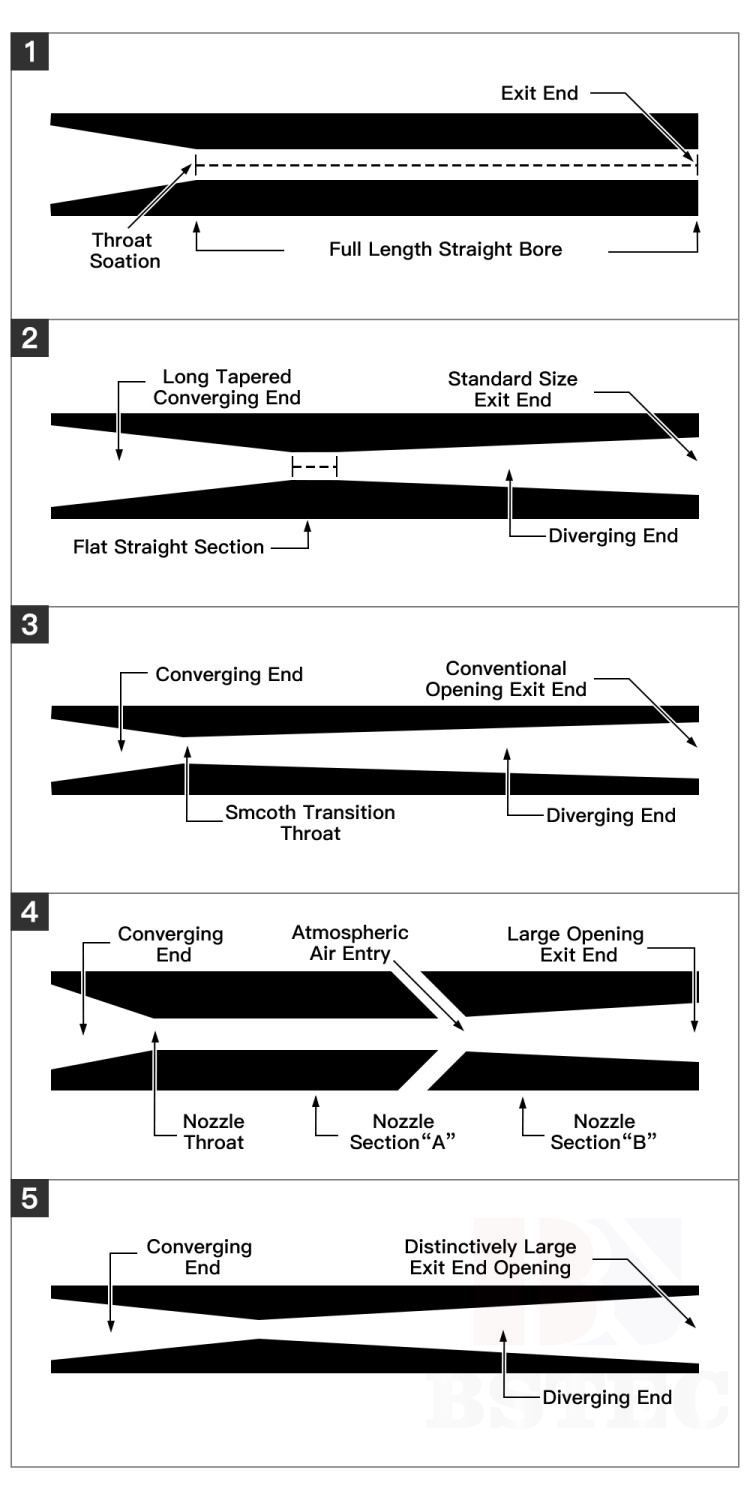

Mphuno zowongoka za Bore(Nambala 1) pangani chithunzi cholimba cha kuphulika kwa malo kapena ntchito ya kabati yophulika. Izi ndi zabwino kwambiri pantchito zing'onozing'ono monga kuyeretsa magawo, kupangira msoko, kuyeretsa zitsulo, masitepe, grillwork, kapena miyala yosema ndi zipangizo zina.

Venturi anali ndi nozzles(Nambala 2 ndi 3) imapanga mawonekedwe a kuphulika kwakukulu ndi kuonjezera liwiro la abrasive ndi 100% pa kukakamizidwa kopatsidwa.

Venturi nozzles ndiye njira yabwino kwambiri yopangira zinthu zambiri mukaphulitsa malo akuluakulu. Ma venturi awiri ndi mphuno zapakhosi ndi mitundu yowonjezeredwa yamtundu wautali wa venturi.

Thekawiri venturikalembedwe (Nambala 4) titha kuganiziridwa ngati ma nozzles awiri motsatizana okhala ndi mpata ndi mabowo pakati kuti alole kuyika kwa mpweya mu gawo lakumunsi la mphuno. Mapeto otuluka nawonso ndi otakata kuposa ochiritsira nozzle. Zosintha zonsezi zimapangidwira kuti ziwonjezere kukula kwa mawonekedwe a kuphulika ndikuchepetsa kutayika kwa liwiro la abrasive.

Ziphuphu zazikulu zapakhosi(Nambala 5) imakhala ndi khosi lalikulu lolowera komanso njira yayikulu yotulukira. Akamafananizidwa ndi payipi yofananira, amatha kukulitsa zokolola ndi 15% pamanozzles okhala ndi mmero wocheperako. Ndibwinonso kukhala ndi ma nozzles okhala ndi madontho othina monga ma latisi a mkwatibwi, kuseri kwa ma flanges, kapena mapaipi amkati. Ogwiritsa ntchito ambiri amawononga ma abrasives ndi nthawi kudikirira kuti ricochet agwire ntchitoyo. Zimatenga nthawi yochepa kuti musinthe kukhala aangle nozzlenthawi zonse imachira msanga, ndipo nthawi yonse yogwira ntchito imachepetsedwa.

3. Sankhani Zida za Nozzle

Mukazindikira kukula kwa nozzle ndi mawonekedwe ake, muyenera kuganizirazakuthupiliner ya nozzle imapangidwa ndi. Zinthu zitatu zazikuluzikulu posankha zida zoyenera zokhala ndi nozzle ndi kulimba, kukana kukhudzidwa, komanso mtengo.

Kusankhidwa kwa zinthu za nozzle kumatengera zomwe mwasankha, momwe mumaphulitsira kangati, kukula kwa ntchito, komanso kulimba kwa malo ogwirira ntchito. Nawa malangizo ogwiritsira ntchito pazinthu zosiyanasiyana.

Tungsten carbide nozzles:Mutha perekani moyo wautali komanso zachuma pamene kusagwira bwino sikungapewedwe. Oyenera kuphulitsa slag, galasi, ndi mineral abrasives.

Silicon carbidenozzles:Imasamva komanso yolimba ngati tungsten carbide, koma pafupifupi gawo limodzi mwa magawo atatu a kulemera kwa tungsten carbide nozzles. Chisankho chabwino kwambiri pamene ogwira ntchito akugwira ntchito kwa nthawi yayitali ndipo amakonda phokoso lopepuka.

Boron carbide nozzles:Zolimba kwambiri komanso zolimba, koma zolimba. Boron carbide ndi yabwino kwa abrasives aukali monga aluminiyamu oxide ndi osankhidwa mchere aggregates pamene kugwira monyanyira kungapewedwe. Boron carbide nthawi zambiri imavala tungsten carbide kasanu mpaka khumi ndi silicon carbide kuwiri kapena katatu pamene ma abrasives aukali amagwiritsidwa ntchito. Mtengo ndi wapamwamba kwambiri pakati pawo.

4. Sankhani Ulusi ndi Jacket

Pomaliza, muyenera kusankha zinthu za jekete kuteteza bore. Muyeneranso kuganizira kuti ndi mtundu uti wa ulusi womwe ukugwirizana bwino ndi zosowa zanu zoboola mchenga: ulusi wopyapyala kapena ulusi wokhuthala.

1) Jacket ya Nozzle

Jacket ya Aluminium:Ma jekete a aluminiyamu amapereka chitetezo chokwanira kwambiri pakuwonongeka kwamphamvu muzopepuka.

Jacket yachitsulo:Ma jekete achitsulo amapereka chitetezo chokwanira kwambiri pakuwonongeka kwamphamvu mu heavyweight.

Jacket ya Rubber:Jekete la rabara ndilopepuka pomwe limaperekabe chitetezo champhamvu.

2) Mtundu wa Ulusi

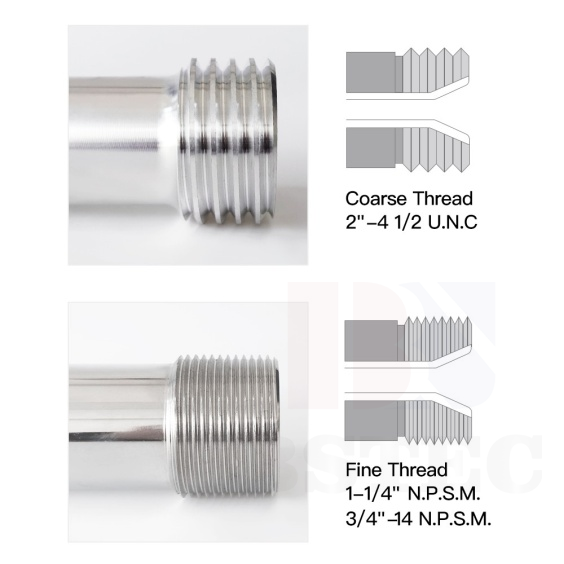

Coarse (Contractor) Ulusi

Ulusi wokhazikika pamafakitale pa ulusi wa 4½ pa inchi (TPI) (114mm), kalembedwe kameneka kamachepetsa kwambiri mwayi wodutsana ndipo ndikosavuta kuyiyika.

Ulusi Wabwino(NPSM ulusi)

National Standard Free-Fitting Straight Mechanical Pipe Thread (NPSM) ndi ulusi wowongoka wa Makampani omwe amagwiritsidwa ntchito kwambiri ku North America.

MAGANIZO OTSIRIZA

Mpweya waukulu ndi ma nozzles akulu amatsogolera kumitengo yayikulu yopangira, koma mawonekedwe a bowolo ndizomwe zimatsimikizira kuthamanga kwa tinthu tating'onoting'ono ndi kukula kwa mawonekedwe a kuphulika.

Pazonse, palibe nozzle yabwino kwambiri, mfundo yofunika ndikupeza ma nozzles oyenera kwambiri kuti mugwiritse ntchito.