The Industrial Buyer's Guide to Replacement Air Filter Cartridges

The Industrial Buyer's Guide to Replacement Air Filter Cartridges | CNBSTEC

The complete industrial buyer's guide to replacement air filter cartridges for sandblasting. Learn about specs, safety standards, selection, and why CNBSTEC is your trusted technical partner.

In the industrial world, knowledge is power and safety is paramount. For those responsible for procuring replacement air filter cartridges for breathing air systems, this guide serves as your comprehensive reference. We will move beyond the basics to provide a deep understanding of the product, the standards that govern it, and the selection process—empowering you to make confident, informed decisions that protect your workforce and your bottom line. Consider this your essential handbook for respiratory safety procurement.

Chapter 1: The Anatomy of Performance: What's Inside a Quality Cartridge?

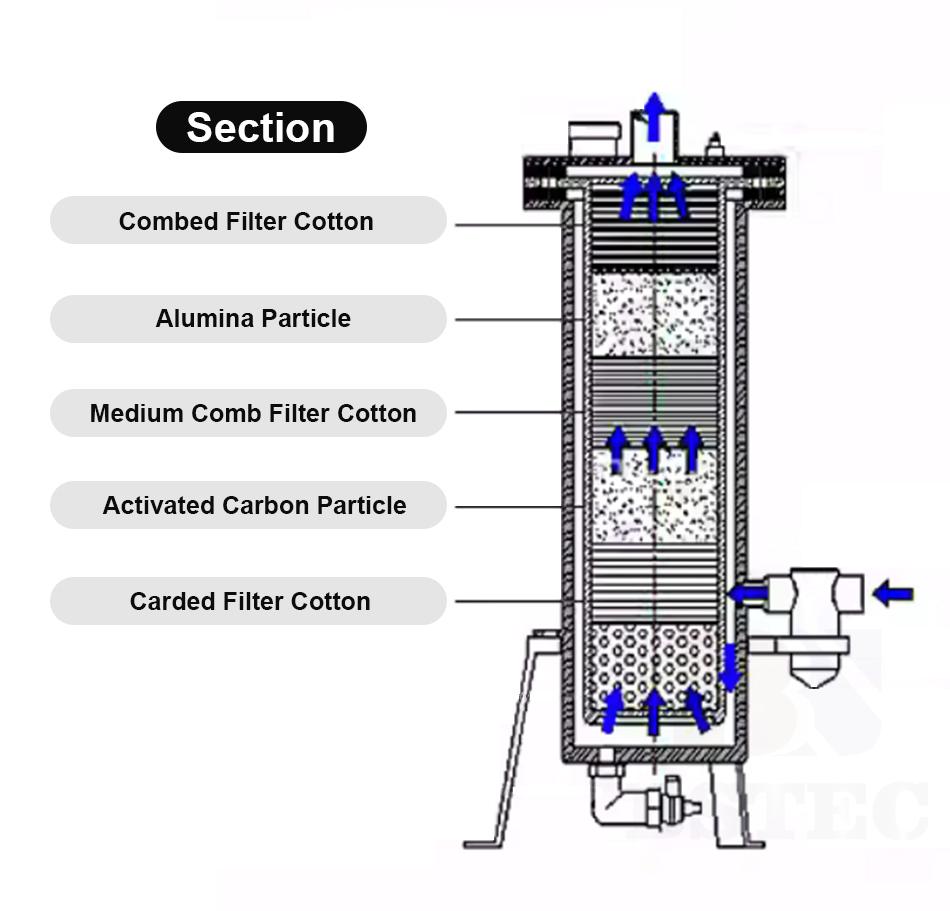

Understanding the components is the first step to evaluating quality. A superior cartridge is a multi-stage marvel of engineering:

▷Pre-Filter/Coalescing Stage: Typically made of combed filter cotton or glass fiber, this layer captures bulk liquid aerosols and solid particulates, causing them to coalesce and drain.

▷Deep-Bed Adsorption Stage: The heart of the cartridge. A dense pack of high-quality activated carbon (with a high iodine value) and often alumina (desiccant) removes oil vapors, odors, and other gaseous contaminants through adsorption.

▷Robust Construction: High-strength polymer end caps with precision-molded threads and seals are crucial. They prevent flexing, cracking, and most importantly, air bypass, which would render the entire cartridge useless.

Chapter 2: The Non-Negotiable Standards: OSHA, NIOSH, and You

Compliance is not optional. For sandblasting and other industrial applications, the mandatory standard is OSHA 29 CFR 1910.134 Appendix D for Grade D breathing air. This standard specifies maximum allowable levels for:

Carbon Monoxide (CO): ≤ 20 ppm

Carbon Dioxide (CO₂): ≤ 1,000 ppm

Condensed Hydrocarbons (Oil Mist): ≤ 5 mg/m³

Lack of Odor: Air must be free of pronounced odor.

Your supplier must provide test documentation proving their cartridges produce air that meets these thresholds. Never work with a supplier that cannot immediately provide this proof.

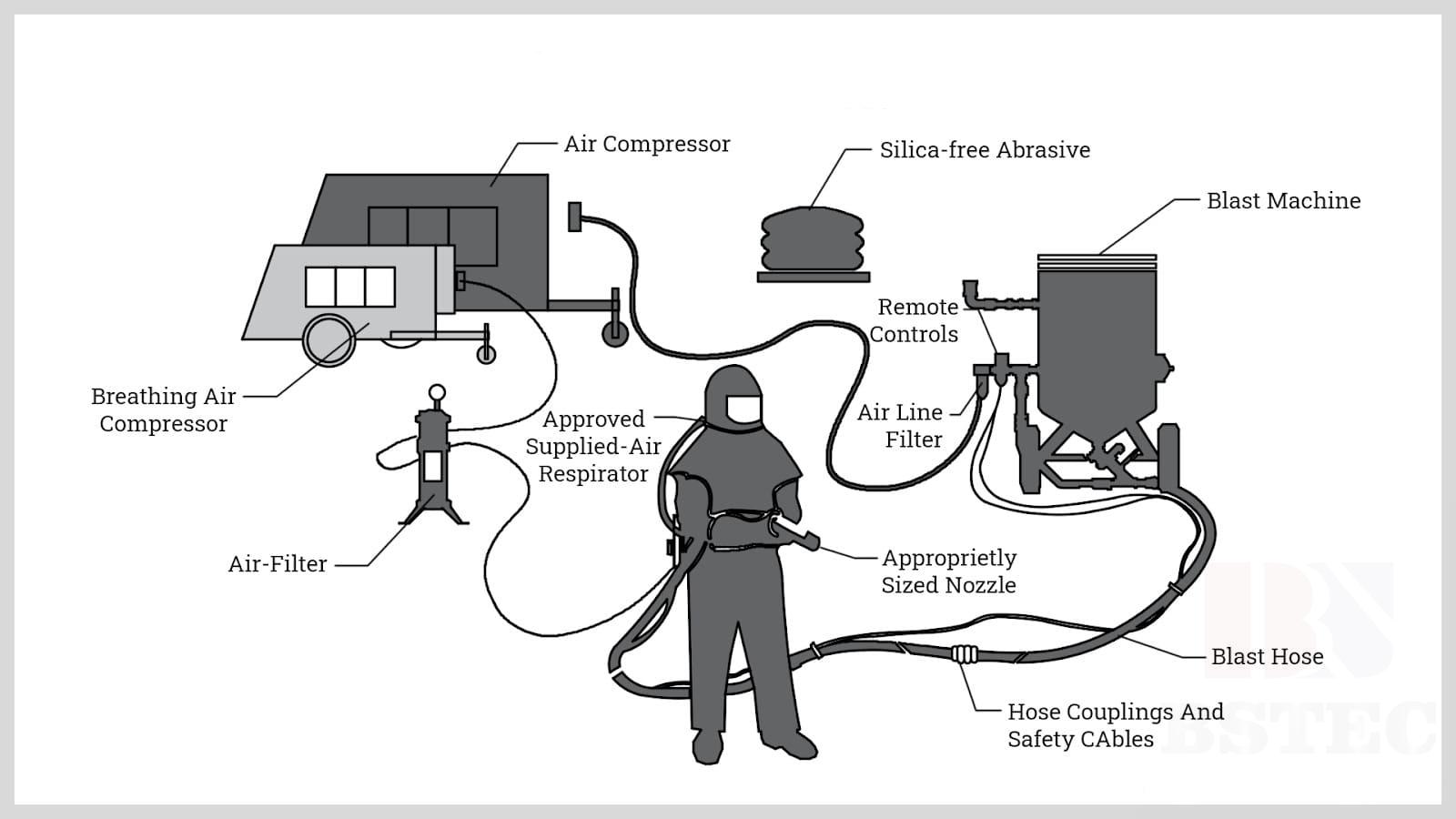

Chapter 3: Application Deep Dive: The Sandblaster's Unique Needs

While the principles of air filtration are universal, sandblasting presents a uniquely harsh environment that demands specific performance:

▷High Moisture Load: Compressed air contains concentrated water vapor that must be removed to prevent equipment corrosion and protect the carbon bed.

▷Heavy Oil Aerosols: Lubricated compressors are common, introducing a significant load of oil mist and vapor.

Continuous, High-Flow Demand: Sandblasting operations consume large volumes of air, pushing cartridges to their limits.

Therefore, your cartridge must have exceptional coalescing efficiency and a high-capacity carbon bed specifically engineered for these severe conditions.

Chapter 4: The Procurement Playbook: A Step-by-Step Selection Process

▷Audit & Identify: List all your filter housing models and their locations.

▷Prioritize Specifications: Your top criteria are: OSHA Compliance > OEM Compatibility > Material Quality (Iodine Value) > Service Life.

▷Source Suppliers: Seek partners, not just vendors. Look for those with sandblasting expertise.

▷Ask the Right Questions: Use our "10 Questions" guide to vet them thoroughly.

▷Analyze Quotes holistically: Calculate Total Cost of Ownership (TCO), not just unit price. Factor in expected lifespan, your labor cost for changes, and the cost of potential downtime.

▷Order Samples: Test compatibility and performance in one housing before committing to a bulk order.

Chapter 5: Installation, Monitoring, and Replacement Best Practices

Installation: Always use gloves to prevent oils from your skin contaminating the new cartridge. Hand-tighten firmly according to the housing manufacturer's instructions to ensure a proper seal without over-tightening.

Monitoring: Note the installation date and compressor hours. Be alert for signs of saturation: odor, taste, or a noticeable drop in airflow/pressure.

Replacement: Adhere strictly to the "400 hours or 3 months" rule. This is a maximum under ideal conditions. In harsh environments, change more frequently. Never exceed this interval.

Why CNBSTEC is Your Ideal Technical Partner

CNBSTEC is not just a manufacturer; we are specialists in industrial air safety. Our replacement air filter cartridges are engineered from the ground up for severe-duty applications like abrasive blasting. We use a scientific blend of materials—combed cotton, high-iodine-value activated carbon, and alumina—to create a product that consistently exceeds industry standards. We provide full compliance documentation, guarantee compatibility with major housing brands, and offer expert technical support from professionals who speak your language. We understand your challenges because we've dedicated ourselves to solving them.

Empowerment through education is the goal of this guide. You now possess the knowledge to navigate the market not as a mere purchaser, but as an expert buyer. You can demand quality, verify performance, and calculate true value. When you specify replacement air filter cartridges, choose a partner that matches your expertise and commitment to safety. Choose CNBSTEC. Contact us today to request your free compatibility guide and sample evaluation.