Top 10 Abrasive Sandblasting Nozzles for Industrial Efficiency in 2025

Top 10 Abrasive Sandblasting Nozzles for Industrial Efficiency in 2025

Introduction: The Critical Role of Nozzle Selection

In industrial surface preparation, sandblasting nozzles are precision components that directly impact operational costs and productivity. With 2025's advanced materials and designs, selecting the optimal nozzle can reduce media consumption by up to 30% while extending equipment lifespan.

Super Wear-resistant series: Suitable for high-intensity continuous operation

1. Tungsten Carbide Nozzles: The Heavy-Duty Champion

√Lifespan: 10- 20x longer than steel

√Optimal for: Steel grit, aluminum oxide

√Industrial applications: Shipbuilding, bridge maintenance

√Key advantage: Lowest cost-per-hour despite higher upfront price

2. Boron Carbide Nozzles: Precision Engineering Solution

√Hardness: 50% greater than tungsten carbide

√Specialty: Aerospace component restoration

√Operational note: Requires careful handling due to brittleness

Economical and practical: Preferred for small and medium-sized projects

3. Ceramic Nozzles: The Cost-Effective Performer

√Economic value: 1/3 the price of carbide

√Best paired with: Glass beads, crushed garnet

√Typical lifespan: 100-200 operational hours

4. Silicon Carbide Nozzles: Lightweight Precision

√Weight reduction: 40% lighter than metal alternatives

√Ergonomic benefit: Reduces operator fatigue

√Ideal for: Automotive restoration shops

Special design: Addressing professional needs

5. Steel Nozzles: The Budget Stopgap

√Replacement frequency: Every 10-20 hours

√Appropriate use: Emergency repairs, low-volume operations

√Cost warning: False economy for continuous use

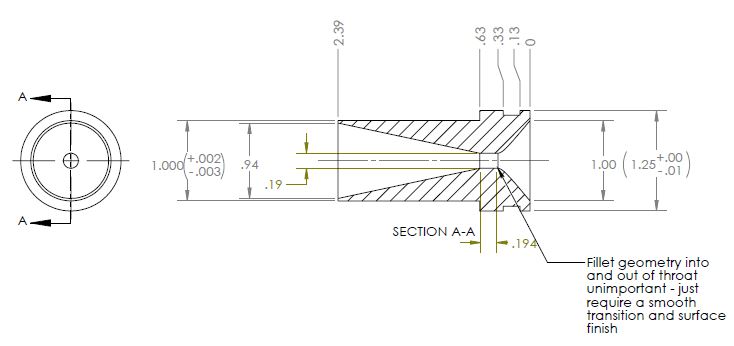

6. Venturi Nozzles: Velocity Optimized

√Efficiency gain: 30% faster cleaning

√Airflow science: Accelerates media via Bernoulli principle

√Project fit: Large surface area treatments

Professional-level solutions

7. Angled Nozzles: Access Solutions

√Angles available: 15°-90° configurations

√Critical for: Pipeline interiors, ship compartments

√Combo suggestion: Paired with extension arms

8. Double-Wall Cooled Nozzles: Thermal Management

√Cooling method: Integrated water jacket

√Temperature range: Withstands 200°C+ environments

√Primary users: Steel mill maintenance teams

9. Wide-Throat Nozzles: Clog Prevention

√Bore diameter: 30-50% wider than standard

√Media compatibility: Slag, coarse garnet

√Maintenance benefit: Reduces downtime

10. Hybrid Nozzles: Custom Performance

√Material combos: Carbide liner with steel housing

√Customization: Available for specific PSI requirements

√Procurement tip: Ask OEMs about tailored solutions

Selection Matrix: Matching Nozzles to Needs

Operational Priority | Recommended Nozzle | Cost-Per-Hour |

Maximum durability | Tungsten carbide | $0.18 |

Precision finishes | Boron carbide | $0.32 |

Budget constraints | Ceramic | $0.12 |

Difficult access | Angled carbide | $0.25 |

Maintenance Protocol for Peak Performance

√Daily: Measure bore diameter (+0.5mm = replace)

√Weekly: Inspect for ovalization

√Storage: Hang vertically in climate-controlled area

Procurement Strategy for 2025

√Bulk discounts: Available for 50+ units

√OEM partnerships: Custom bore sizing

√Tech support: Free abrasive compatibility consulting