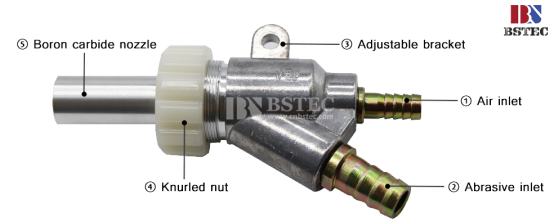

V Type Suction Blast Spay Gun Kit

description

Suction Sand Blasting Gun, designed for fast efficient sand blasting, liquid or air cleaning of parts and surfaces, is a king of powerful tool for removing corrosion, mill scale, old paint, heat treatment residue, carbon buildup, tool marks, burrs and many other materials. It’s also widely used in the making of frosted glass in the factory.

Suitable Applications

1.Works with most recyclable blast media – steel grit and shot, silicon carbide, garnet, aluminum oxide, glass bead, and ceramics

2.The removal of paint, rust, scale, and carbon, etc.

V Type Suction Blast Spay Gun Kit

Type V blasting gun directs a high-speed mixture of air and abrasive to quickly remove corrosion, coatings, heat treatment residue or other substances.

Novel Features

1.The gun keeps the air jet and blast nozzle precisely aligned to maximize blast efficiency and minimize gun-body wear

2. A knurled nut at the gun outlet allows the operator to change nozzles without tools

3. Adjustable bracket allows gun fixture in all possible blast directions

4. Accepts a variety of nozzles and extensions such as boron carbide/silicon carbide /tungsten carbide/ceramics nozzle inserts, so the operator can select the best nozzle size and nozzle composition for the application

5. Gun components such as air jet, nozzle insert, nozzle sleeve, and flange nut can be replaced separately to save costs

Operation:

1.With all related equipment correctly assembled and tested, the operator points the nozzle at the surface to be cleaned and presses the remote control handle to begin blasting.

2.The operator holds the nozzle 18 to 36 inches from the surface and moves it smoothly at a rate that produces the desired cleanliness. Each pass should overlap slightly.

3.The operator must replace the nozzle once the orifice wears 1/16-inch beyond its original size.

As a leading provider of sandblasting solutions, we take pride in offering our clients unparalleled quality, efficiency, and customer service.

1. Expertise and Experience

With over 12 years of experience in the sandblasting industry, our team of skilled technicians has the expertise to handle a wide range of projects, from small-scale touch-ups to large-scale industrial applications. We stay up-to-date with the latest techniques and equipment to ensure the best possible results for our clients.

2. Quality Assurance

At the core of our business is a commitment to quality. We use only the highest-grade abrasives and adhere to strict safety and quality control protocols to deliver consistent, flawless results every time. Our rigorous quality assurance measures give you the peace of mind that your project will be completed to the highest standards.

3. Unmatched Efficiency

We understand that time is of the essence in today's fast-paced business environment. That's why we have streamlined our processes to maximize efficiency and minimize downtime. Our state-of-the-art equipment and well-trained crew allow us to complete projects quickly, without compromising the quality of our work.

4. Exceptional Customer Service

At our company, we believe that excellent customer service is the foundation of a successful business relationship. From the initial consultation to the final inspection, our team is dedicated to providing personalized attention and addressing your every need. We are committed to exceeding your expectations and ensuring your complete satisfaction.

5. Versatile Solutions

Whether you require sandblasting for surface preparation, rust removal, or texture enhancement, our comprehensive range of services can meet your unique requirements.

6. Competitive Pricing

At our company, we believe in providing exceptional value to our clients. We offer competitive pricing without compromising the quality of our work, ensuring you receive the best possible return on your investment.

Experience the difference our expertise, quality, and customer-centric approach can make. Get Quote immediately

1. Are you a trading company or manufacturer?

We are a factory, mainly producing tungsten carbide, boron carbide, and silicon carbide products. And we also do trading on related accessories according to customers' requirements.

2. How can we guarantee the quality?

Always a pre-production sample before mass production; Always final Inspection before shipment

3. Why should you buy from us, not from other suppliers?

Rich experience in product and exporting ISO quality, good price, and fast delivery, wide production scope for optional; save cost, save energy, save time; gain high-quality products, gain more business opportunity, win the market!

4. How long is your delivery time?

Generally, it is 3~5 days if the goods are in stock; or it is 15-25 days if the goods are not in stock, depending on order quantity.

5. Do you provide samples? Is it free or extra?

Generally, we don't provide free samples. But we can deduct sample costs from your bulk orders.

6. What are your payment terms and method?

Payment Less than or equal to 1000USD, 100% in advance. Payment Greater than or equal to 1000USD, 30% T/T in advance, balance before shipment. We accept T/T, L/C, Alipay, PayPal, Western Union, WeChat, and so on.