Learn The Internal Pipe Blasting Nozzle from Six Aspects

Learn the Internal Pipe Blasting Nozzle from Six Aspects

Nozzles can be applied to various types of surface finishing, not only on but also inside the surface, like the pipe. In this case, we need to use the device, internal pipe blasting nozzle with different related tools,to achieve our desired surface roughness.

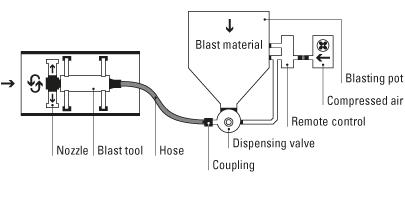

The Principle

As the process of other sandblasting, it involves three key elements of internal pipe blasting, an air compressor, blast materials, and an internal pipe blast nozzle. Air is firstly pushed out to carry abrasive particles from the blast material pot. Then the mixture flows to the internal pipe blast nozzle by a connecting hose. Finally, the abrasive particles are sprayed to clean the interior of the pipe ranging in size 19mm to 900mm by the deflection tip of the nozzle. The tip produces a blast pattern to cone out which means the abrasive is dispersed in 360 degrees, to promote cleaning more efficiently.

The Structure

The common style, it is mainly divided into three parts including a deflection tip, a nozzle body, and a coupling that includes coarse thread or fine thread. For another special style, the rotating blast head in place of the common deflection tip to shoot abrasives.

The Liner Materials

The liner material includes two types, Boron Carbide (B4C) and Tungsten Carbide (TC). B4C has lightweight, high temperature, wear, and corrosion resistance. Its hardness is second only to diamond. TC also has high hardness, wear resistance at a relatively cheap price. The case is usually made of Aluminum.

The Tools

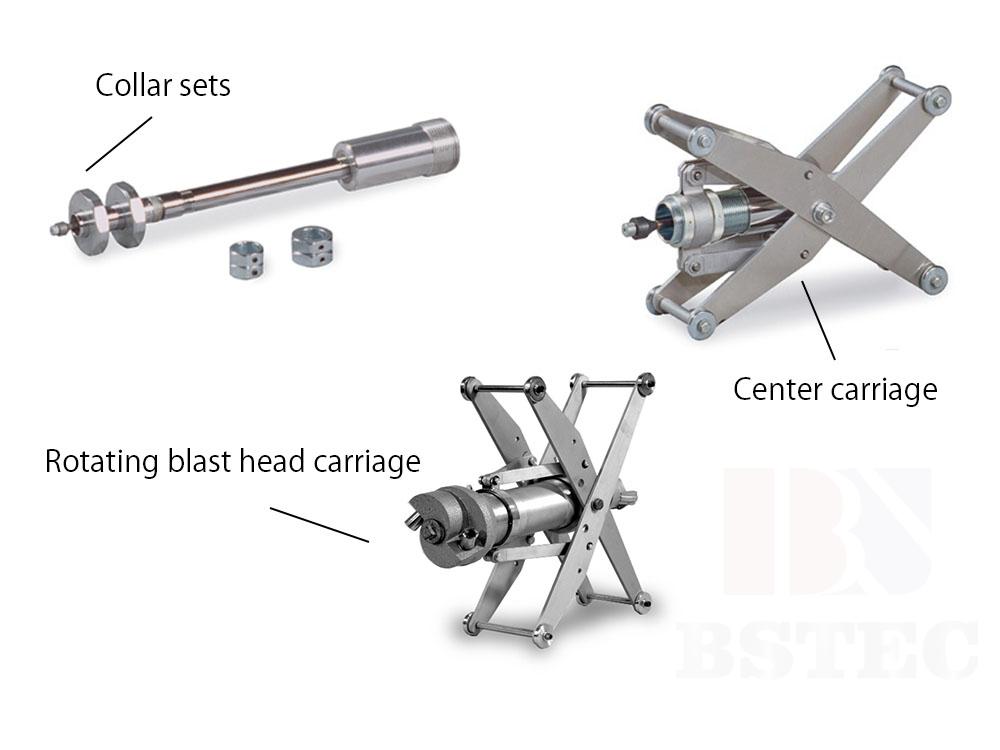

Different pipe internal diameters need corresponding nozzles and related tools.

19-50mm pipe I.D.: For the internal pipe diameters ranging from 19mm to 50mm, the blasting process needs lance style nozzles and collar sets for locating the nozzle within a pipe. According to different sizes of pipes, we need to equip with suitable collar sets.

50-135mm pipe I.D.: For the internal pipe diameters ranging from 50 to 135mm, it has two choices of blasting tools. One is a nozzle with large collar sets (The largest one is available for 135 pipe I.D.). The other is a nozzle with a center carriage that looks like a scissor. As the function of the collar set, the centering carriage is to enable the nozzle to move smoothly in the pipe.

135-900mm pipe I.D.: For this case, it needs nozzles with a rotating head carriage that has several spinning heads to shoot abrasive.(picture tools)

The Operations

For the surface finishing of internal pipe, it is commonly applied to remove rust, which enables mechanical parts to improve a lot. Sandblasting of the inner wall is mainly a high-speed spraying method based on the principle of air compression as power. The abrasives that are used in the removal of rust have various types like garnet sand, quartz sand, copper mine, etc. The detailed procedure is as follows.

Step1: Before sandblasting, the surface of the internal pipe shall be cleaned first. Surface cleaning is important for it directly affects the adhesion of the whole coating.

Step2: Exposure to the sun is helpful to delay the service life of the coating. In addition, there are other methods like solvent cleaning, acid pickling.

Step3: Prepare the air compressor, then align the nozzle with the surface to be treated, and keep the distance at about 15 ~ 30 cm. We can use suitable blast tools to locate nozzles within pipes moving smoothly.

Step4: Sandblasting has an impact and cutting effect inside the pipe, and the surface can reach certain cleanliness and different roughness.

Attention

1. During sandblasting construction, personal safety protection wearing shall be worn to avoid injury to the body.

2. During construction, it should keep at least two people to avoid an emergency that can’t deal with in one person.

3. Before using the air compressor, the ventilation pipe and sandblasting machine need to be checked for sealing.

4. The air pressure of the air compressor as far as possible doesn’t exceed 0.8MPa, and the air valve needs to be opened slowly when using the air compressor.