How to Choose the Best Sandblasting Nozzle for Your Business Needs

How to Choose the Best Sandblasting Nozzle for Your Business Needs

Introduction: Why Nozzle Selection Matters

Sandblasting nozzles may seem like small components, but they play a pivotal role in determining your operation's productivity, cost-efficiency, and finish quality. Selecting the wrong nozzle can lead to premature wear, inconsistent blasting patterns, and increased operating costs. With various materials, shapes, and sizes available, making an informed choice requires understanding your specific blasting requirements. This comprehensive 1,200-word guide walks you through the five critical factors for selecting the perfect sandblasting nozzle for your business.

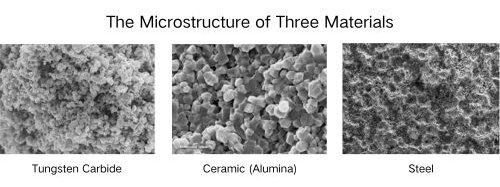

1. Matching Nozzle Material to Your Abrasive Media

The hardness and type of abrasive media directly determine which nozzle material will deliver optimal performance and longevity.

Material Selection Guide:

Tungsten Carbide (WC): The gold standard for hard abrasives like steel grit (60-80 HRC) and aluminum oxide. Offers 500-1,000 hours of service life – 5-10× longer than ceramic alternatives.

Boron Carbide (B₄C): Even harder than WC (3,500 HV vs. 2,600 HV), ideal for ultra-fine finishes in aerospace applications. Brittle but unmatched for precision work.

Ceramic (Al₂O₃): Cost-effective for medium abrasives (glass beads, garnet) with 100-200 hour lifespan. Prone to chipping if dropped.

Steel: Budget option for soft media (plastic beads, walnut shells) but lasts only 10-20 hours with hard abrasives.

Technical Insight:

WC's cobalt matrix structure absorbs impact energy while maintaining bore integrity, whereas ceramic's crystalline structure makes it vulnerable to fracture.

2. Nozzle Geometry: Shape Determines Performance

Three primary nozzle designs each serve distinct purposes:

Performance Comparison Table:

Type | Bore Design | Velocity | Best Application | Coverage |

Straight | Cylindrical | Medium | Precision stripping, detail work | Concentrated |

Venturi | Converging-diverging | High (MACH 2+) | Large surface cleaning | Wide |

Wide-Throat | Flared exit | Low | Heavy/viscous media | Extra-wide |

Case Study:

A pipeline coating facility increased productivity by 35% after switching from straight to venturi nozzles, thanks to the accelerated particle velocity.

3. Size Optimization: Balancing Pressure & Efficiency

Nozzle diameter directly affects three key parameters:

Size vs. Performance Relationship:

Bore Diameter | PSI Range | CFM Requirement | Media Consumption |

3/16" (4.8mm) | 60-100 | 10-15 | 200-300 lb/hr |

1/4" (6.4mm) | 80-120 | 15-20 | 300-450 lb/hr |

3/8" (9.5mm) | 100-150 | 20-30 | 600-800 lb/hr |

Pro Tip:

Use this formula to calculate optimal size:

CFM = (Nozzle Area in in²) × (PSI × 0.5)

Example: 1/4" nozzle at 100 PSI needs ≈18 CFM

4. Operational Economics: Calculating True Costs

While tungsten carbide nozzles cost 3-5× more than ceramic upfront, their total cost per hour tells a different story:

Cost Analysis Over 1,000 Hours:

Factor | Tungsten Carbide | Ceramic | Steel |

Nozzle Cost | $120 | $30 | $10 |

Replacements Needed | 1 | 5 | 50 |

Downtime Cost | $50 | $250 | $2,500 |

Total Cost | $170 | $400 | $3,010 |

5. Application-Specific Recommendations

Tailor your selection to industry requirements:

Industry Solutions Matrix:

Industry | Recommended Nozzle | Why? |

Shipbuilding | WC Venturi (1/2") | Handles steel grit at high volume |

Automotive | B₄C Straight (5/16") | Precision without overspray |

Oil & Gas | WC Wide-Throat (3/8") | Resists clogging with wet slurry |

Art Restoration | Ceramic Straight (1/4") | Gentle enough for delicate surfaces |

Maintenance Protocol to Maximize ROI

Even premium nozzles fail prematurely without proper care:

7-Point Maintenance Checklist:

Daily: Measure bore wear with plug gauges (replace if >5% expansion)

Weekly: Rotate nozzles in multi-gun setups for even wear

Post-Use: Clean with nylon brushes (never metal)

Storage: Hang vertically in climate-controlled cabinets

Documentation: Log hours used for predictive replacement

Training: Educate operators on proper handling techniques

Spares: Keep 2-3 backup nozzles to avoid downtime

Conclusion: Making the Smart Investment

Choosing the right sandblasting nozzle requires balancing:

✔ Abrasive Hardness vs. Nozzle Material

✔ Project Size vs. Nozzle Geometry

✔ Budget Constraints vs. Long-term ROI

Final Recommendation:

For most industrial applications processing hard abrasives, tungsten carbide venturi nozzles deliver the best combination of speed and durability. Conduct a 30-day trial comparing your current setup to WC nozzles – most operations achieve payback within 3-6 months through reduced downtime and media savings.