Let's Explore Blast Venturi Nozzle

Let's Explore Blast Venturi Nozzle

--Understand venturi nozzle from three aspects

Abrasive Blasting, as a surface finishing process that generally involves the use of an air compressor and blasting machine, is to spray abrasive particles to a surface needed to become smoother or rougher.

Nozzle, as an important element of blasting, has developed according to the needs of times. There were only straight bore nozzles in the mid-1950s. However, the blasting operator found the drawback of them for being worn and eroded inside. And at that time, a more efficient blast pattern, venturi nozzle, has appeared. So what are venturi nozzles? Let’s look at it in detail.

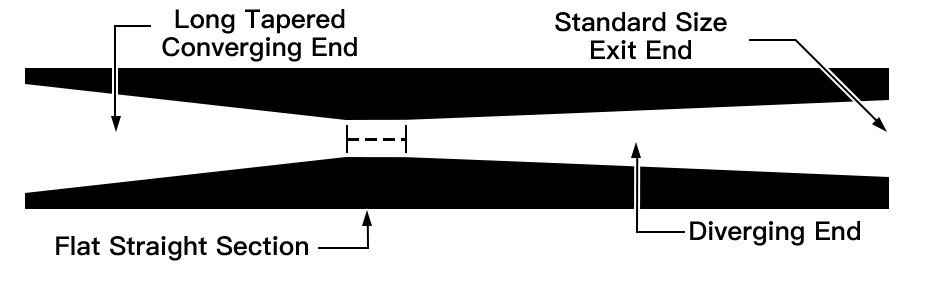

Structure of Venturi Nozzle

In terms of appearance, the venturi nozzle is divided into three sections. First, it starts with a long tapered converging inlet, followed by a short flat straight section, and then has a long diverging end which becomes wider when reaching up close to the outlet of the nozzle. Such a design helps to increase work efficiency by 70%, and how is this achieved?

Air and abrasive enter the nozzle through the long converging inlet and then flow to the short straight section while the pressure decreases at that time, which results in a pressure difference between inside and outside. This pressure difference provides an external force for the abrasive particles. When the abrasive leaves the nozzle, the speed is twice higher than that of the straight bore nozzle. So the surface becomes clean more efficiently.

Types of Venturi Nozzle

The venturi blasting nozzle has a variety of categories classified from different angles. For example, from the perspective of the inlet, it is divided into the single-inlet and double-inlets. It is generally divided into boron carbide, silicon carbide, and tungsten carbide in liner materials. Moreover, the thread type is roughly divided into coarse thread and fine thread.

1.Classified by inlet

1.1 Single-inlet venturi nozzle

Single-inlet venturi nozzle, follow the normal Venturi Effect, means it has only one way drawing air and abrasive to flow into straight flat section.

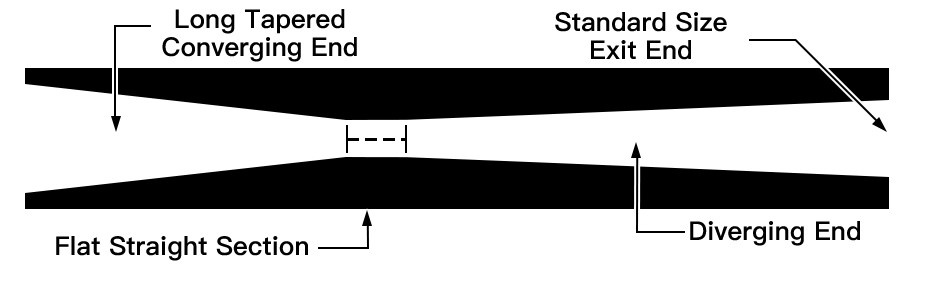

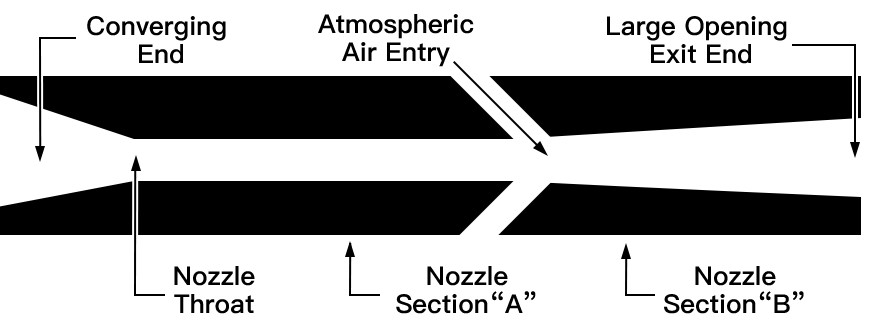

1.2 Double-inlets venturi nozzle

As shown in the above figure, it has two nozzles connected with a gap between them. There are eight small holes around the gap to facilitate drawing surrounding air into the nozzle, which makes air ejected larger than the compressed air drawn the nozzle, thus the speed of abrasive is improved leading to more efficient surface cleaning.

2. Classified by liner materials

The three most popular materials used today for blast nozzles are boron carbide, silicon carbide, and tungsten carbide.

2.1 Boron carbide venturi nozzle

Boron carbide nozzle features high hardness, excellent wear, and abrasion resistance. From the appearance, it is a little weak light.

2.2 Silicon carbide venturi nozzle

Silicon carbide nozzle is characteristically of stable chemical properties and good wear resistance. The surface of the silicon carbide nozzle is roughly similar to that of boron carbide. In careful comparison, the silicon carbide is darker with strong reflectivity. Its advantage is that it can easily mold into various shapes, and has a low price, while the wear resistance is 1/3 to1/2 of that of hot pressing nozzles.

2.3 Tungsten carbide venturi nozzle

Tungsten carbide nozzle features high hardness, good wear resistance, and stable structure needed less maintenance. It is a new deal choice for blasting operators because it has excellent durability and wear when using the hard abrasive.

3. Classified by thread

It can be roughly divided into coarse thread and fine thread.

3.1 Coarse Thread 2”-4 1/2 U.N.C.

Coarse thread has a larger gap between each thread, implying it is more suitable to bear large tensile and impact force.

3.2 Fine Thread 1-1/4” N.P.S.M

Fine thread means the smaller gap between each thread, which can reduce particles leakage.

4. Classified by length

4.1 Long venturi nozzle

As the name shows, it is longer, generally ranging from 135mm to 230mm.

4.2 Short venturi nozzle

It is short, and the length generally ranges from 81mm to 135mm.

Applications of blast venturi nozzle

Abrasive blasting is a surface finishing process including smoothing or roughing a surface, shaping a surface and removing contaminants from the surface. It is used in many fields, like removing rust away from contaminated metal surfaces, jeans fabric surface treatment, and glass etching, etc.

Different working needs diverse types of nozzle. Choosing the suitable one is the key to increase work efficiency.

Welcome to find ZZbetter for high-quality venturi nozzles.