The Portable Pipe Blasting Revolution: How Internal Pipe Tools Are Transforming Industry

The Portable Pipe Blasting Revolution: How Internal Pipe Tools Are Transforming Industry

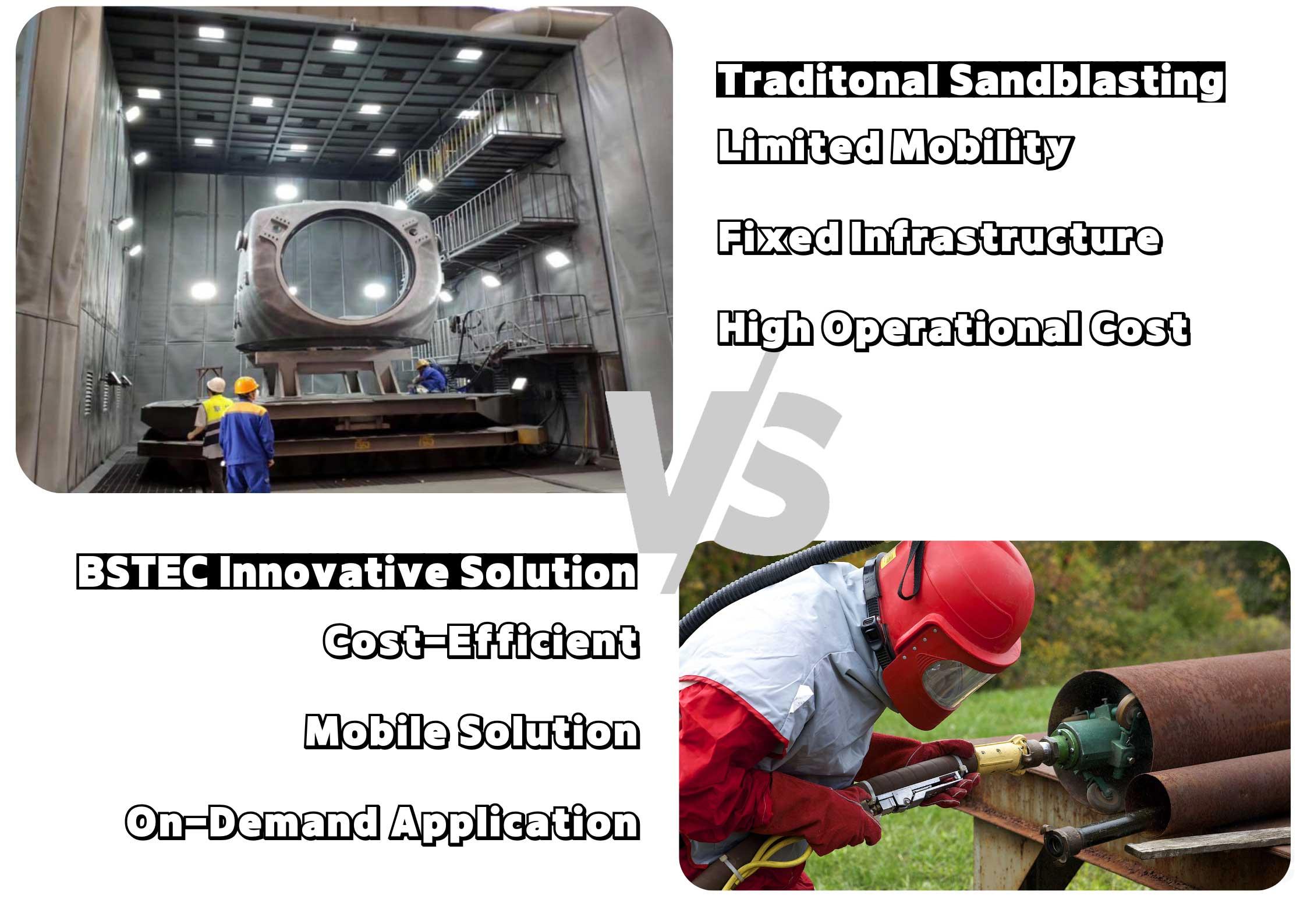

The surface treatment industry is undergoing a quiet revolution. For decades, pipe maintenance and corrosion protection have been synonymous with massive equipment, lengthy downtime, and significant logistical challenges. Traditional blasting methods often required moving pipes to specialized facilities or setting up complex containment systems on-site. This approach not only increased project timelines but also drove up costs substantially. However, a new era of portable pipe blasting technology is changing everything.

The Limitations of Traditional Methods

Conventional pipe blasting operations typically involve either transporting pipes to a fixed facility or bringing large, trailer-mounted blasting systems to the site. Both scenarios present considerable challenges. Transporting pipes creates logistical nightmares, especially for large-diameter or welded-in-place piping systems. Bringing large equipment to remote locations often requires special permits, additional manpower, and extensive setup time. These traditional methods frequently result in:

●Extended project timelines due to setup and teardown requirements

●Higher costs associated with transportation and equipment mobilization

●Limited access to confined or difficult-to-reach areas

●Potential damage to pipes during transportation

●Environmental concerns with containment and cleanup

The Portable Revolution Emerges

The development of advanced portable internal pipe blasting tools represents a paradigm shift in how the industry approaches surface preparation. These innovative systems combine powerful blasting performance with unprecedented mobility and flexibility. Modern portable units are designed to be compact, lightweight, and easily transportable to even the most remote job sites.

The revolution isn't just about making equipment smaller—it's about completely reimagining how surface preparation can be performed. Today's portable internal pipe tools incorporate advanced nozzle designs, efficient abrasive recovery systems, and ergonomic features that maximize productivity while minimizing operator fatigue.

CNBSTEC's Innovative Solution

At the forefront of this revolution is CNBSTEC's Portable Internal Pipe Blast Tool, which embodies the key advantages driving industry adoption:

Unmatched Mobility

Weighing significantly less than traditional equipment, our portable system can be easily transported by a single vehicle and operated by a minimal crew. This mobility is particularly valuable for remote projects, emergency repairs, and sites with limited access.

Rapid Deployment

Where traditional systems might require days to set up, our portable tool can be operational within hours. Quick-connect features and intuitive controls ensure that work begins almost immediately upon arrival at the job site.

Superior Performance in Confined Spaces

The compact design allows operators to work in tight spaces where conventional equipment simply cannot fit. This is particularly valuable in plant maintenance situations where pipes are often surrounded by other equipment and structures.

Reduced Environmental Impact

Advanced containment and recycling features minimize abrasive waste and dust emissions, helping projects meet increasingly stringent environmental regulations.

Transforming Industry Practices

The implications of this portable revolution are profound across multiple sectors:

Oil and Gas

Field maintenance teams can now perform on-site repairs without removing pipes from service, dramatically reducing downtime and production losses. The ability to work in remote locations without sacrificing performance has been particularly transformative for this industry.

Shipbuilding and Marine

Shipyards are using portable systems for internal tank and pipe maintenance without moving vessels from dry docks. This capability has significantly accelerated maintenance schedules and reduced costs.

Power Generation

Plant maintenance during scheduled outages has become more efficient with portable systems that can access complex pipe networks around other equipment.

Water Treatment

Municipal water systems can now perform maintenance without taking critical infrastructure completely offline, ensuring continuous service to communities.

The Future is Portable

As technology continues to advance, the portable blasting revolution shows no signs of slowing. Future developments will likely focus on even greater efficiency, enhanced dust collection systems, and smarter technologies that integrate with digital maintenance platforms.

The CNBSTEC Portable Internal Pipe Blast Tool represents more than just another piece of equipment—it embodies a fundamental shift in how industry approaches surface preparation. By combining portability with professional-grade performance, this technology is helping companies reduce costs, improve efficiency, and meet their maintenance goals with unprecedented flexibility.

For forward-thinking companies looking to stay competitive in today's demanding market, embracing the portable blasting revolution isn't just an option—it's becoming a necessity. The ability to perform high-quality surface preparation anywhere, anytime, is rapidly becoming the new standard in industrial maintenance.