Automated vs. Manual Sandblasting: Which Nozzle Type Fits Your Operation

Automated vs. Manual Sandblasting: Which Nozzle Type Fits Your Operation

Introduction: The Great Automation Decision

In modern surface preparation, the choice between automated and manual sandblasting systems represents a critical crossroads for operational efficiency. This comprehensive analysis examines the five fundamental factors that determine which nozzle type - and by extension, which blasting method - delivers optimal performance for your specific application. With 20% of industrial operations now transitioning to automated solutions annually, understanding these key differences becomes essential for maintaining competitive advantage.

1. Nozzle Durability: The Wear Resistance Imperative

Material Science Behind Operational Longevity

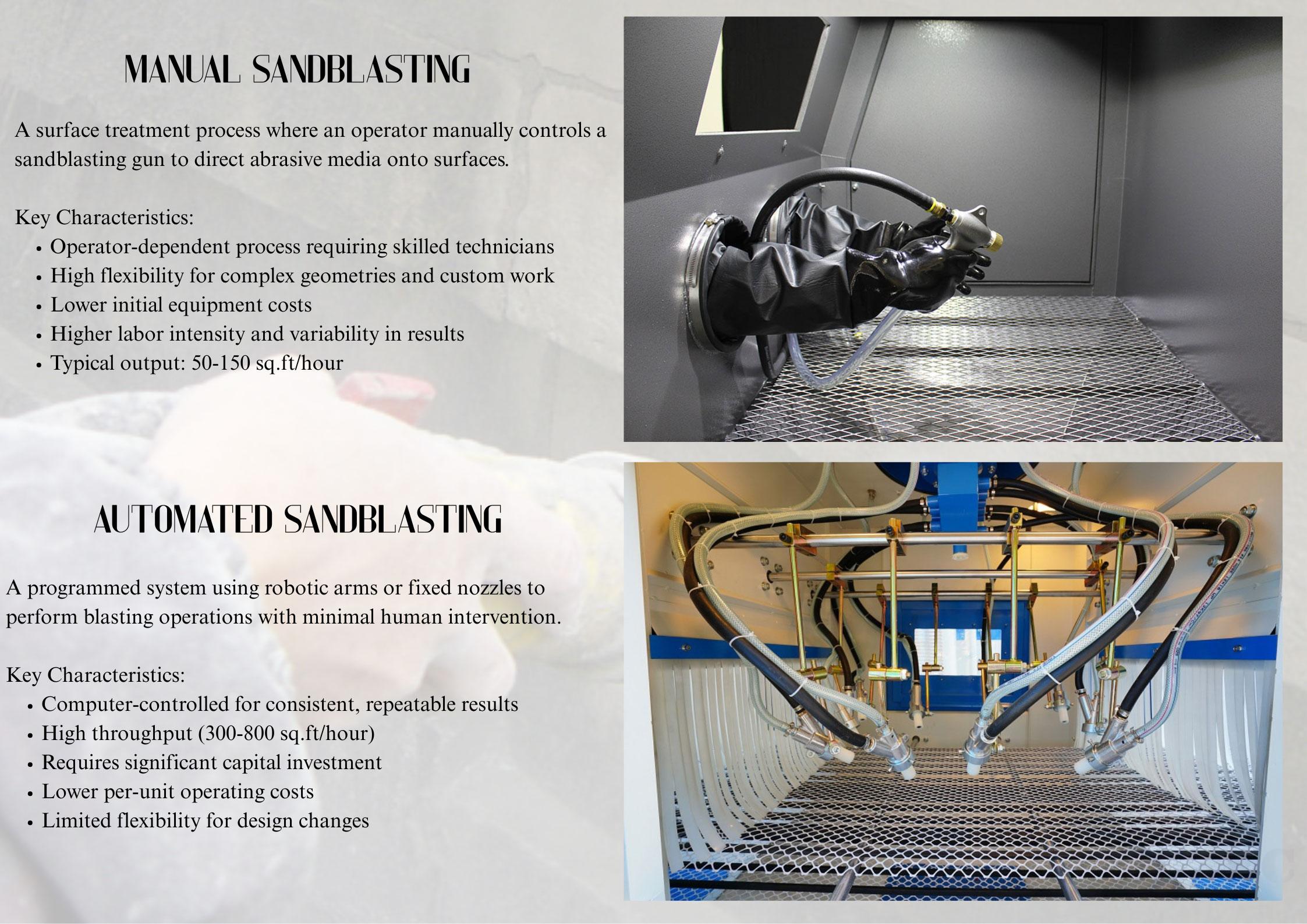

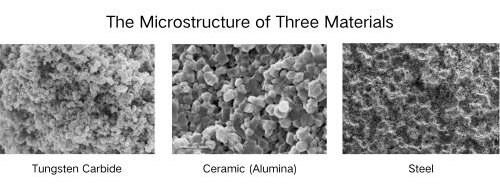

Automated systems demand superior nozzle materials due to their continuous operation:

✅Tungsten carbide (WC): 500-1,000 hour lifespan under constant use

✅Boron carbide (B₄C): 800-1,500 hours for ultra-high-end systems

✅Ceramic: Only suitable for manual intermittent use (100-200 hours)

Technical Insight:

The cobalt matrix in tungsten carbide nozzles absorbs vibrational energy in robotic systems, while ceramic's crystalline structure fractures under sustained mechanical stress. Automated operations experience 10× higher nozzle wear rates than manual applications.

Case Example:

German automotive supplier Continental reduced nozzle replacement costs by 68% after switching to tungsten carbide in their robotic blasting cells.

2. Precision Engineering Requirements

Tolerance Standards Across Applications

Specification | Automated Nozzles | Manual Nozzles |

Bore Diameter Tolerance | ±0.01mm | ±0.05mm |

Surface Profile Consistency | Ra ±1.2μm | Ra ±3.5μm |

Angular Deviation | <0.5° | <2° |

Critical Consideration:

Venturi nozzles in automated systems maintain ±2% media velocity variance versus ±15% in manual operations, directly impacting coating adhesion standards.

3. Productivity Benchmarks

Throughput Comparison in Industrial Settings

Automated System Capabilities:

✅500-800 sq ft/hour coverage

✅30-40% faster than manual

✅10-15% media savings

Manual Operation Realities:

✅200-350 sq ft/hour

✅Better for complex geometries

✅Higher operator skill dependency

Productivity Tradeoff:

While automated systems process 2.5× more surface area, manual methods maintain superiority for intricate components like turbine blades or sculpture restoration.

4. Financial Analysis: Total Cost of Ownership

5-Year Operational Cost Breakdown

Cost Factor | Automated | Manual |

Equipment | $250,000 | $5,000 |

Nozzles (5yr) | $3,200 | $8,750 |

Labor | $75,000 | $375,000 |

Media Waste | $18,000 | $27,000 |

Total | $346,200 | $415,750 |

ROI Insight:

Automation breaks even at 14-18 months for operations blasting >400 sq ft daily. Small shops processing<100 sq ft/day find manual more economical.

5. Application-Specific Selection Guide

Decision Matrix for Common Industries

Automation Preferred:

1. Automotive (frame coating)

2. Wind turbine (tower sections)

3 . Pipeline (exterior preparation)

Manual Recommended:

1. Aerospace (engine components)

2 .Art conservation (delicate surfaces)

3 . Prototype development

Emerging Solution:

Hybrid systems now combine robotic consistency with manual flexibility - particularly effective in shipbuilding for hull vs. compartment work.

Implementation Roadmap

Transitioning Between Systems

Step 1: Conduct 30-day throughput analysis

Step 2: Validate nozzle compatibility

Step 3: Pilot test with 1 automated cell

Step 4: Train technicians on dual systems

Step 5: Full-scale implementation

This technical and financial analysis provides operations managers with a data-driven framework for evaluating sandblasting automation. By combining measurable performance metrics with real-world implementation case studies, this guide serves as both a strategic planning tool and a practical transition manual.