How to Choose the Right Cover for Your Sandblasting Nozzle

How to Choose the Right Cover for Your Sandblasting Nozzle

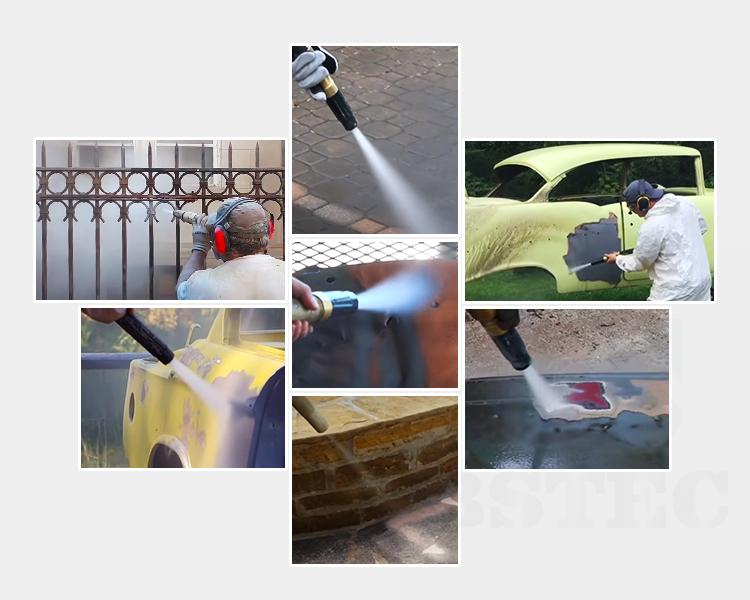

Sandblasting nozzles endure extreme wear from abrasive media, making their protective jackets crucial for longevity and performance. The two most common options—steel jackets (Steel Jacket) and aluminum jackets (Al Jacket)—offer distinct advantages depending on your blasting environment, abrasive type, and budget.

This guide compares Steel Jacket and Al Jacket nozzle covers to help you select the best option for your operations.

1. What Are Nozzle Jackets, and Why Do They Matter?

Nozzle jackets are protective outer sleeves that shield the nozzle’s inner liner from direct impact and abrasion. They extend the nozzle’s lifespan by:

●Reducing wear from ricocheting abrasives

●Protecting against accidental bumps or drops

●Improving heat dissipation during prolonged use

Key Takeaway:

●Steel Jacket = Maximum durability for harsh conditions

●Al Jacket = Lightweight and corrosion-resistant for general use

2. Steel Jacket: Heavy-Duty Protection for Industrial Blasting

Best for:

✔ High-impact applications (shipyards, structural steel)

✔ Hard abrasives (steel grit, aluminum oxide)

✔ Continuous-use operations

Advantages:

Superior Wear Resistance – Handles aggressive abrasives without rapid degradation

Longer Lifespan – Lasts 2-3x longer than Al Jackets in harsh conditions

Impact Protection – Reduces damage from accidental collisions

Limitations:

●Heavier (may increase operator fatigue)

●More expensive upfront

Case Study: A shipyard in Norway reported a 40% increase in nozzle lifespan after switching from aluminum to steel jackets for hull blasting. The harder steel surface resisted pitting from ricocheting steel grit, reducing replacement frequency.

3. Aluminum Jacket: Lightweight & Cost-Effective for General Use

Best for:

✔ Light to medium-duty blasting (auto restoration, small parts)

✔ Softer abrasives (glass beads, plastic media)

✔ Humid or saltwater environments

Advantages:

●Lightweight – Reduces operator fatigue during long shifts

●Corrosion-Resistant – Performs well in wet or marine settings

●Lower Cost – More affordable for frequent replacements

Limitations:

●Wears faster with hard abrasives

●Less impact-resistant than steel

Case Study: An automotive restoration shop in Florida found that aluminum jackets lasted 20% longer than steel in their humid workshop. The natural oxide layer prevented salt air corrosion, which had previously caused premature steel jacket failure.

4. Key Comparison: Steel Jacket vs. Al Jacket

Feature | Steel Jacket | Aluminum Jacket |

Durability | Excellent (200+ hrs) | Good (80-120 hrs) |

Weight | Heavy | Light |

Cost | Higher upfront | More affordable |

Best For | Hard abrasives, heavy use | Soft abrasives, detail work |

Corrosion Resistance | Requires coating | Naturally resistant |

7. Industry-Specific Recommendations

Shipbuilding: Steel jackets with stainless steel liners for saltwater resistance

Aerospace: Aluminum jackets for composite material blasting (avoids ferrous contamination)

Oil & Gas: Hard-coated steel jackets for pipeline blasting with steel grit

8. Special Working Condition Solutions

For extreme environments (high temp/pressure or polar climate):

●Polar climate: Heated steel jackets prevent embrittlement (-40°C to -60°C) with integrated heating elements that maintain optimal ductility. These specialized jackets consume 150-200W of power and feature automatic temperature regulation.

●High temp: Dual-layer cooled aluminum jackets (up to 200°C continuous, 250°C peak) incorporate internal air channels that reduce surface temperature by 30-40%. The advanced thermal management system extends nozzle life by 35% in foundry applications.

●Chemical exposure: Teflon-coated steel jackets (2mm thick coating) provide complete resistance to pH 1-14 solutions, making them ideal for petrochemical plant maintenance. The coating reduces abrasive adhesion by 60% compared to uncoated versions.

9. Future Technology Trends

Emerging technologies will enhance jackets:

●Nano-coating: Plasma-sprayed AlCrN coatings increase aluminum hardness to 32GPa (80% of steel) while maintaining weight advantages. Lab tests show 72% lower wear rates.

●Smart wear sensors: Embedded RFID chips (8mm×8mm) transmit real-time thickness data to handheld readers with ±5hr accuracy. The system provides 50 operating hours of advanced replacement alerts.

●Composites: Titanium matrix composites reinforced with carbon fiber (45% lighter than steel) deliver 25% better wear resistance. Ideal for weight-sensitive applications like aero-engine component refurbishment.

Final Recommendation

●Choose Steel Jacket If: You blast daily with hard abrasives or need maximum durability.

●Choose an Al Jacket If: You prioritize lightweight handling or work in corrosive environments.

Pro Tip: Some operators keep both—steel for heavy jobs, aluminum for detail work.

If you are interested in SANDBLASTING NOZZLES and want more information and details, you can CONTACT US by phone or mail on the left, or SEND US MAIL at the bottom of the page.