Reach Every Inch: Superior Blasting for Internal Pipe Surfaces

Reach Every Inch: Superior Blasting for Internal Pipe Surfaces

Achieving complete and uniform surface preparation within pipeline systems represents one of the most significant challenges in industrial maintenance and corrosion protection. Traditional blasting methods frequently fail to address hard-to-reach areas, compromising coating adhesion and leading to premature system failure. The solution lies in advanced internal pipe tool technology, specifically engineered to deliver exceptional blasting performance in confined spaces.

The Challenge of Complete Coverage

Many areas within pipeline networks present exceptional difficulty for proper surface preparation. Elbows, areas behind welds, and the deepest sections of long pipe runs often remain partially treated with conventional methods. This inconsistency in cleaning and profile development directly impacts coating performance, creating potential points for corrosion initiation and coating disbondment. Standard blasting equipment lacks the precision required to ensure comprehensive treatment of every square inch of internal surface.

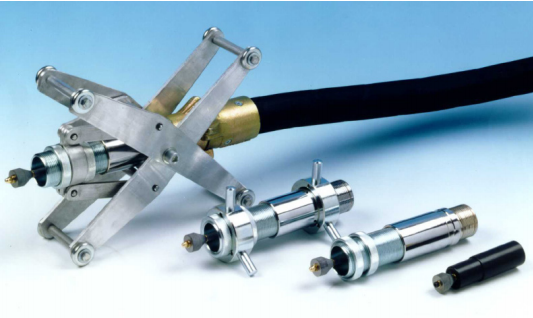

Precision Engineering of Specialized Nozzles

Modern internal pipe nozzle designs address these coverage and consistency challenges directly. Unlike standard nozzles, these specialized blasting nozzle configurations are precision-engineered to optimize abrasive distribution and impact angle. Their unique geometry generates a consistent, controlled abrasive stream that ensures uniform cleaning and anchor profile development, even on the most difficult-to-reach internal surfaces. This advanced internal pipe nozzle technology significantly reduces abrasive waste while maximizing coverage efficiency.

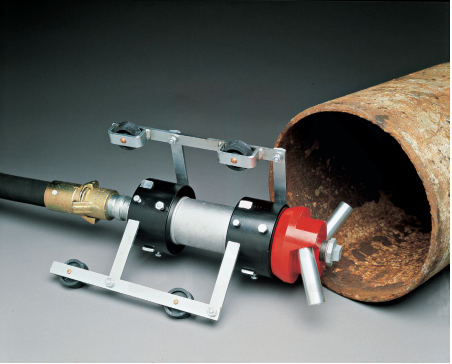

Performance Excellence in Practical Application

When integrated with purpose-built internal pipe tool systems, these specialized nozzles demonstrate remarkable performance characteristics. The tooling maintains optimal nozzle-to-surface distance and angle throughout the operation, ensuring complete coverage regardless of pipe geometry. Whether processing large-diameter pipelines or complex network configurations, the internal pipe nozzle delivers exceptional results. The efficiency of this blasting nozzle technology also contributes to substantially reduced abrasive consumption, lowering operational costs.

Benefits Beyond Surface Coverage

The advantages of advanced internal pipe nozzle systems extend far beyond superior coverage. The consistent surface preparation quality provides the ideal foundation for enhanced coating adhesion, significantly extending protective coating service life. Efficient abrasive utilization reduces waste generation, supporting more sustainable operation practices. Additionally, the durable construction of these blasting nozzle products decreases replacement frequency and maintenance requirements.

Transforming Internal Surface Preparation Standards

As industry demands for reliability and efficiency continue to escalate, the adoption of specialized internal pipe tool systems with advanced nozzle technology has transitioned from optional to essential. These systems ensure every blasting operation meets the highest quality standards, fundamentally transforming the approach to internal surface preparation.

Technical Specifications and Considerations

The effectiveness of any internal pipe nozzle depends on proper specification and operation. Key factors include: Nozzle material composition (tungsten carbide for extended wear resistance), bore size and configuration matching specific application requirements, compatibility with various abrasive types and sizes, pressure rating and flow characteristics, and integration capabilities with different internal pipe tool systems.

Parameter Category | Options & Specifications | Description & Application Guidance |

Core Material | 1. Tungsten Carbide (WC) | 1. Tungsten Carbide: Industry standard. Excellent wear resistance, cost-effective. Ideal for most abrasives (steel grit, shot, garnet). |

Bore Diameter | Standard Range: 6mm - 12mm | 1. Small Bore (6-8mm): Focused abrasive stream, higher impact force. Best for thick coatings/rust or small-diameter pipes. Lower abrasive consumption. |

Operating Pressure | Optimal Range: 100-125 psi (7-8.6 bar) | Nozzles perform best at 100-125 psi. Continuous operation near or above 150 psi will drastically reduce service life. Pressure must match abrasive type and bore size. |

Airflow Requirement | @ 100 psi (7 bar) | Critical for compressor sizing. Ensure stable airflow (CFM) delivery, not just pressure (PSI). Insufficient airflow causes drastic efficiency loss. |

Connection Type | Standard: 1-1/4" UNF Thread | 1-1/4" UNF is industry universal for compatibility. Quick-disconnect options maximize operational efficiency and reduce downtime. |

Service Life | (Using G25 Steel Grit @ 100 psi) | Life is approximate. Actual lifespan depends on abrasive type, pressure, and air cleanliness. Dirty/wet air reduces life significantly. |

Abrasive Compatibility | Excellent: Steel Grit/Shot, Garnet, Olivine | Never use silica sand. Causes extreme nozzle wear and creates hazardous respirable crystalline silica dust (causes silicosis). |

Future Developments in Nozzle Technology

Ongoing research and development in blasting nozzle technology continues to push performance boundaries. Emerging innovations include: Smart nozzle systems with integrated wear sensors, advanced materials offering extended service life, designs optimized for specific abrasive types, configurations enabling reduced energy consumption, and solutions for increasingly challenging pipeline geometries.

The evolution of internal pipe nozzle technology remains crucial for addressing the industry's growing demands for efficiency, precision, and environmental responsibility in surface preparation operations.