Why Tungsten Carbide Nozzles Outlast Ceramic & Steel in Abrasive Blasting

Why Tungsten Carbide Nozzles Outlast Ceramic & Steel in Abrasive Blasting

Abrasive blasting is a critical surface preparation process across industries like shipbuilding, oil & gas, and metal fabrication. While many factors determine blasting efficiency, nozzle selection remains one of the most important - yet often overlooked - decisions. Among all nozzle materials, tungsten carbide (WC) consistently outperforms ceramic and steel alternatives in longevity and cost-effectiveness. This article examines the five key reasons why WC nozzles dominate industrial blasting applications, supported by technical data and real-world case studies.

1. Material Science: The Hardness Advantage

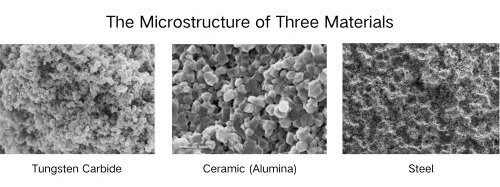

Tungsten carbide's exceptional wear resistance stems from its unique material properties. With a Vickers hardness rating of 2600 HV, WC significantly surpasses ceramic (2000 HV) and hardened steel (800 HV). This hardness comes from WC's composite microstructure - tungsten carbide particles bonded in a cobalt matrix, creating an extremely dense material that resists abrasive particle erosion.

Technical Comparison:

Tungsten Carbide: 9-9.5 Mohs hardness

Ceramic (Alumina): 8.5-9 Mohs

Steel: 7-8 Mohs

In practical terms, this means WC nozzles maintain their bore diameter and profile 5-10 times longer than ceramic nozzles when processing hard abrasives like aluminum oxide or steel grit.

2. Operational Longevity: Documented Performance

Field tests across multiple industries demonstrate WC's superior lifespan:

Nozzle Material | Average Lifespan (Hours) |

Tungsten Carbide | 500-1000 |

Ceramic | 100-200 |

Steel 10-20 | 10-20 |

A case study at a European shipyard showed that switching from ceramic to WC nozzles reduced replacement frequency from every 2 weeks to every 3 months, while maintaining consistent blasting quality. The reduced downtime alone justified the higher initial investment within six months.

3. Cost Analysis: Long-Term Savings

While WC nozzles carry a higher upfront cost ($80-$120 vs $15-$50 for ceramic), their extended service life delivers substantial savings:

Cost per 1,000 Operational Hours:

Tungsten Carbide: $120

Ceramic: $250

Steel: $500

These calculations account for:

✅Nozzle replacement costs

✅Labor for changes

✅Production downtime

✅Media consumption (WC maintains optimal airflow longer)

4. Performance Under Extreme Conditions

WC nozzles maintain integrity where other materials fail:

Thermal Stability:

✅Withstands continuous operation at 500°C+

✅Ceramic becomes brittle above 300°C

✅Steel softens at high temperatures

Impact Resistance:

✅3x more shock-resistant than ceramic

✅No cracking from accidental drops

✅Chemical Resistance:

✅Impervious to rust and corrosion

✅Ideal for wet blasting and marine environments

5. Optimal Applications for WC Nozzles

Tungsten carbide proves most valuable in:

Heavy-Duty Scenarios:

✅Continuous 8+ hour shifts

✅High-pressure systems (100+ PSI)

✅Hard abrasives (steel grit, aluminum oxide)

When to Consider Alternatives:

✅Soft media (walnut shells, plastic beads)

✅Very low-pressure applications (<60 PSI)

✅Extreme budget constraints

Application Match: When to Choose Tungsten Carbide

WC nozzles excel in:

✅ Continuous heavy production (8+ hr/day)

✅ Hard abrasives (steel grit, aluminum oxide)

✅ High-pressure systems (100+ PSI)

Consider alternatives when:

❌ Processing soft media (walnut shells, plastic beads)

❌ Budget constraints outweigh long-term savings

Maintenance Best Practices

Maximize WC nozzle lifespan with proper care:

Daily Inspection:

✅Check the bore diameter with a go/no-go gauge

✅Measure for ovalization

Cleaning Protocol:

✅Use nylon brushes (never metal)

✅Remove all abrasive residue

Proper Storage:

✅Hang vertically in dry conditions

✅Use anti-vibration foam

Operational Tips:

✅Avoid dry running without media

✅Maintain consistent air pressure

Conclusion: The Smart Investment

For industrial operations processing hard abrasives under demanding conditions, tungsten carbide nozzles deliver unmatched value. While the initial cost is higher, the combination of extended lifespan, reduced downtime, and consistent performance makes WC the clear choice for cost-conscious operations.

Final Recommendation:

Conduct a trial comparing WC to your current nozzles - most operations see ROI within 3-6 months. For bulk purchasing or custom configurations, consult with specialized manufacturers to optimize your nozzle specification.