Where to Buy Breathing Air Filter Cartridges for Sandblasting [2025 Guide]

Where to Buy Breathing Air Filter Cartridges for Sandblasting [2025 Guide]

Introduction

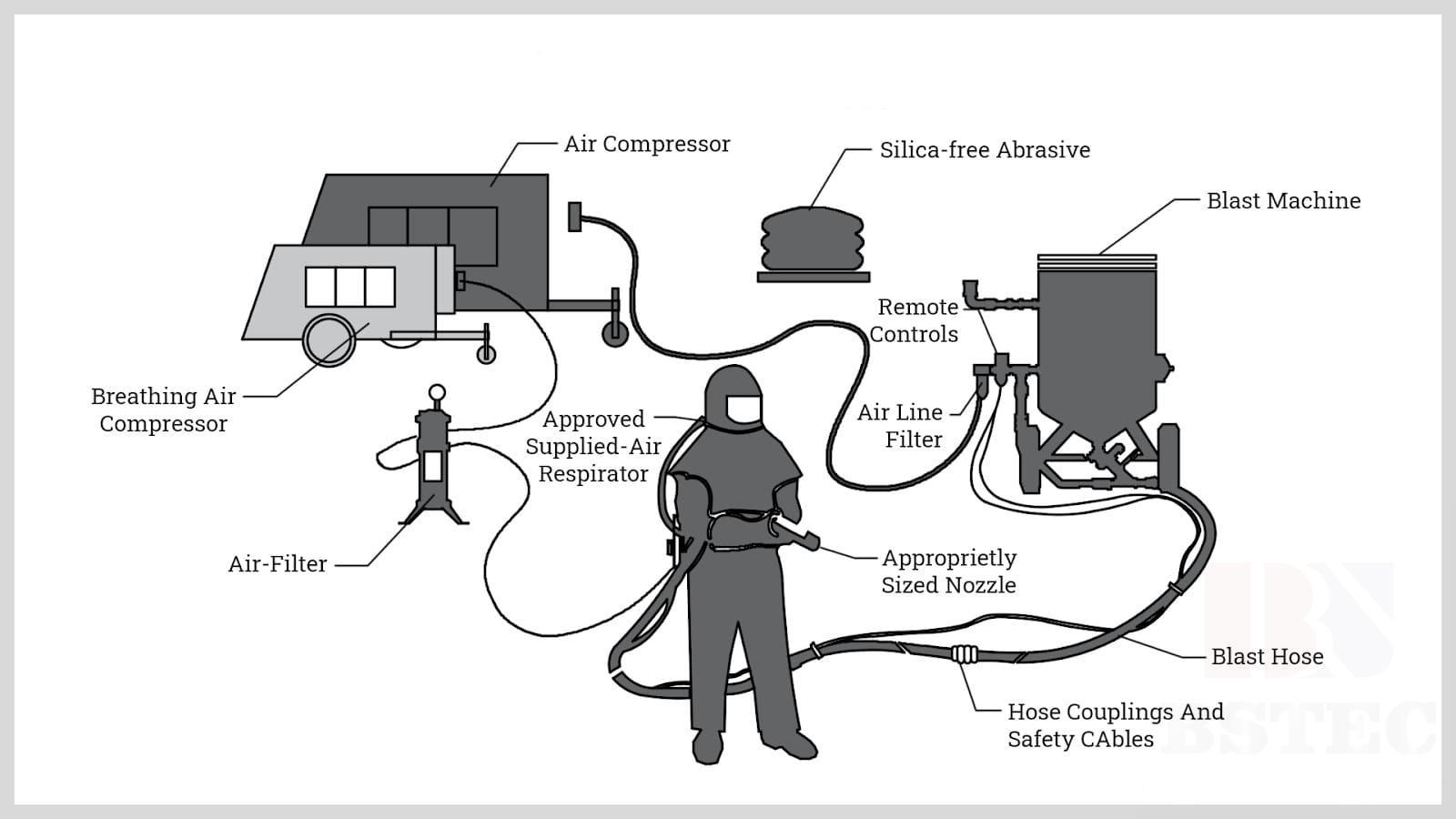

In the high-stakes environment of sandblasting, compressed air purity is not an option—it is an absolute necessity for survival. Operators rely on breathing air systems to protect them from a complex mixture of hazards: oil aerosols, water vapor, particulate matter, and potential carbon monoxide contamination. The replacement air filter cartridge is the final and most critical defense, a consumable component that carries the immense responsibility of ensuring life-supporting air quality. Procuring these cartridges in bulk is therefore one of the most significant decisions a safety or procurement manager can make, directly impacting regulatory compliance, operational liability, and most importantly, human health. This guide provides a detailed framework for identifying a supplier capable of meeting the severe demands of the abrasive blasting industry.

The Unique Respiratory Hazards in Abrasive Blasting

The sandblasting process creates an exceptionally challenging environment for air filtration. Compressed air, essential for powering equipment and providing breathable air, can itself become a poison vector if not properly treated. Lubricated compressors introduce oil aerosols and vapors into the air stream. Atmospheric air contains inherent moisture that becomes highly concentrated when compressed. Furthermore, in a grave risk, compressor malfunctions or intake valve issues can lead to carbon monoxide generation from overheated lubricants. A standard industrial filter is utterly inadequate for this multifaceted threat. Only a cartridge engineered with a deep-bed structure, combining coalescing media for liquids and high-capacity adsorbent materials for vapors and gases, can provide the comprehensive protection required by OSHA and other safety regulators. Understanding this specific threat profile is the first step in making an informed procurement decision.

A Three-Pillar Framework for Selecting Your Supplier

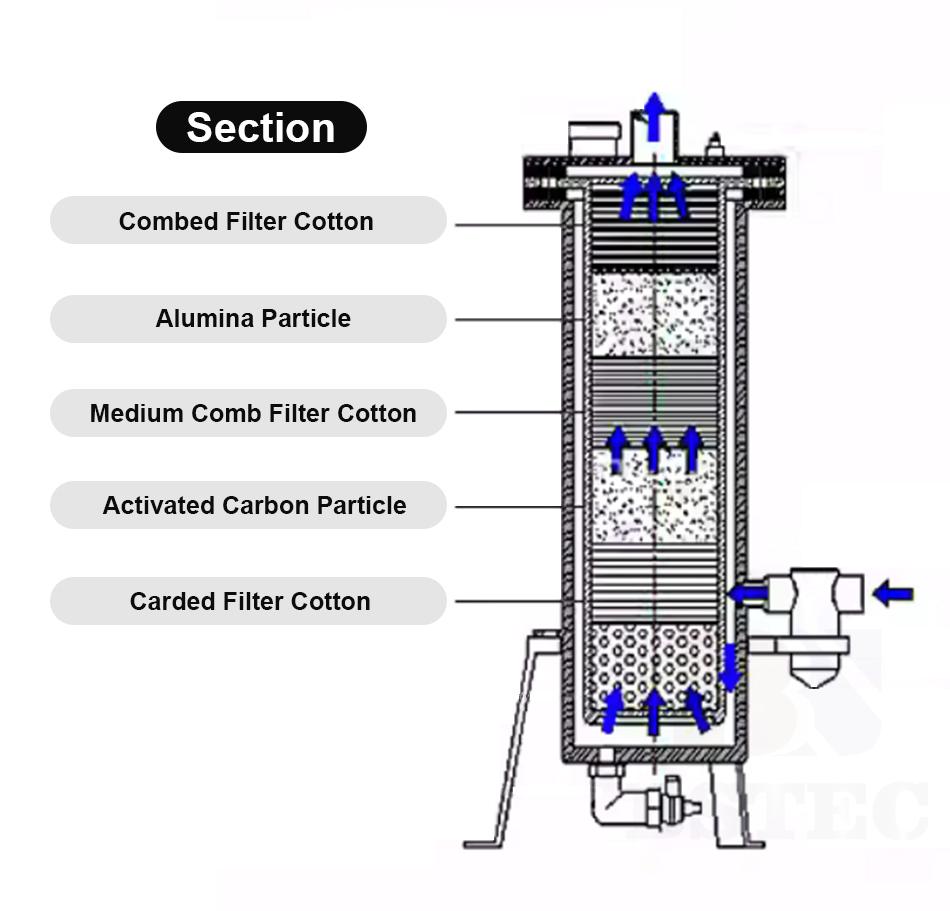

Evaluating a potential bulk supplier requires a rigorous approach based on three non-negotiable pillars. First, Regulatory Certification and Documentation are paramount. The supplier must provide unambiguous documentation that their cartridges produce air meeting OSHA 29 CFR 1910.134 Appendix D Grade D standards. This is not a suggestion but a legal requirement for workplace safety. Second, Technical Design and Material Quality must be scrutinized. Insist on cartridges that utilize a multi-stage design, beginning with a coalescing stage for bulk liquid removal, followed by a deep bed of activated carbon with high surface adsorption capacity for vapors and odors. The construction must include robust end caps and seals to prevent dangerous bypass. Third, OEM Compatibility and Supply Chain Reliability are critical for operational continuity. The cartridges must be precision-engineered as direct replacements for major brands like Clemco, Bullard, Twin Air, and Marco. Furthermore, the supplier must demonstrate a proven ability to fulfill large orders consistently and on time, ensuring you never face a project shutdown due to a lack of critical safety components.

The Economics of Safety: Calculating Total Cost of Ownership

The initial purchase price of a filter cartridge is a misleading metric. The true assessment lies in calculating the Total Cost of Ownership (TCO), which encompasses far more than unit cost. A high-quality cartridge, like those from BSTEC®, offers a superior TCO through several mechanisms. Its extended service life reduces the frequency of change-outs, thereby lowering labor costs and minimizing production downtime. Its consistent high efficiency protects downstream equipment from corrosion and damage, avoiding expensive repairs. Most significantly, its unwavering reliability mitigates the catastrophic financial risks associated with regulatory fines and liability lawsuits resulting from a respiratory safety failure. Investing in quality air filtration is, fundamentally, a powerful risk management and cost-saving strategy.

Engineered for Your Industry: The BSTEC® Advantage

BSTEC® manufactures replacement air filter cartridges with a singular focus on severe-duty applications like abrasive blasting. Our engineering process begins with the selection of premium materials: combed filter cotton for superior particulate coalescence and a high-density blend of activated carbon and alumina for unparalleled adsorption of oil vapors and odors. Each cartridge is constructed to exacting OEM tolerances, ensuring a perfect seal and fit in specified housings to eliminate the risk of air bypass. This commitment to precision manufacturing, combined with our rigorous quality control protocols, guarantees that every cartridge delivers consistent, reliable performance that meets the most stringent safety standards. We don't just sell a product; we provide a certified critical safety component you can trust.

Conclusion and Call to Action

The quality of the air your sandblasting team breathes is the foundation of their safety and your operational integrity. There is no room for compromise. Choosing a bulk supplier for your replacement filter cartridges demands a diligent, informed approach focused on certification, design, and compatibility.

Download our detailed Technical Specification Sheet and Compatibility Matrix to verify that our cartridges meet your exact equipment requirements. For a personalized consultation and to discuss volume pricing, contact our specialized sandblasting safety team today. Let us partner with you to ensure an uninterrupted supply of clean, safe air.