Ba ku san yadda ake zaɓar bututun fashewa ba? Bi matakai huɗu, yana da sauƙi!

Ba ku san yadda ake zaɓar bututun fashewa ba? Bi matakai huɗu, yana da sauƙi!

-- Matakai huɗu sun gaya muku yadda ake zaɓar nozzles masu fashewa masu dacewa

An ƙera nozzles ɗin sandblasting a nau'ikan daban-daban tare da girma dabam da siffofi daga abubuwa daban-daban. Zaɓin madaidaicin bututun yashi na kowane aikace-aikacen shine kawai batun fahimtar masu canji waɗanda ke shafar aikin tsaftacewa da farashin aiki. Idan baku san yadda ake zabar bututun ƙarfe mai dacewa da kanku ba, bi matakai 4 kamar ƙasa.

1. Zaba Girman Bututun Ciki

Lokacin zabar bututun ƙarfe, yana farawa da nakaiska compressor. Da zarar kun fahimci yadda girman compressor ɗinku ke shafar iyawar samarwa, to zaku so ku dubagirman bututun ƙarfe. Zaɓi bututun ƙarfe mai ƙanƙara mai ƙanƙara kuma za ku bar wasu ƙarfin fashewa akan tebur. Ya yi girma na gundura kuma ba za ku rasa matsi don fashewa mai amfani ba.

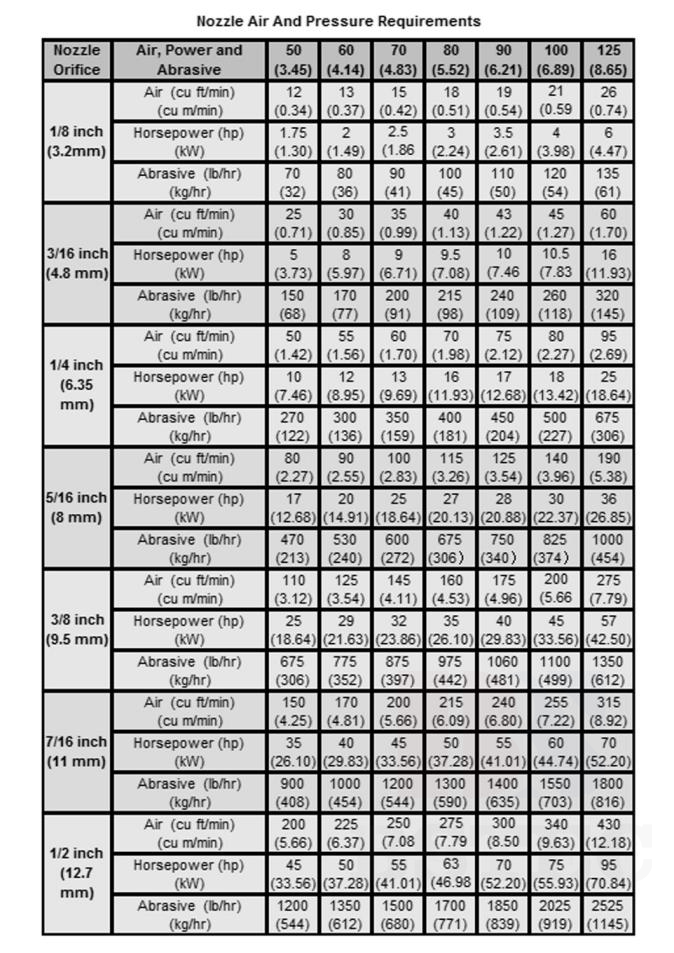

Teburin da ke ƙasa yana nuna alaƙa tsakanin ƙarar iska, girman bututun ƙarfe, da matsa lamba na bututun ƙarfe kuma galibi ana amfani dashi a cikin masana'antar don zaɓar girman bututun ƙarfe. Amfaninsa na haƙiƙa shine zaɓi mafi girman girman bututun ƙarfe don matsa lamban bututun ƙarfe da ake buƙata don aiwatar da aikin.

2. Zaɓi Siffar Nozzles

Na gaba shinesiffar bututun ƙarfe. Nozzles sun zo cikin siffofi na asali guda biyu:Skai tsayekumaVenturi, tare da bambance-bambancen bambance-bambancen Venturi nozzles.

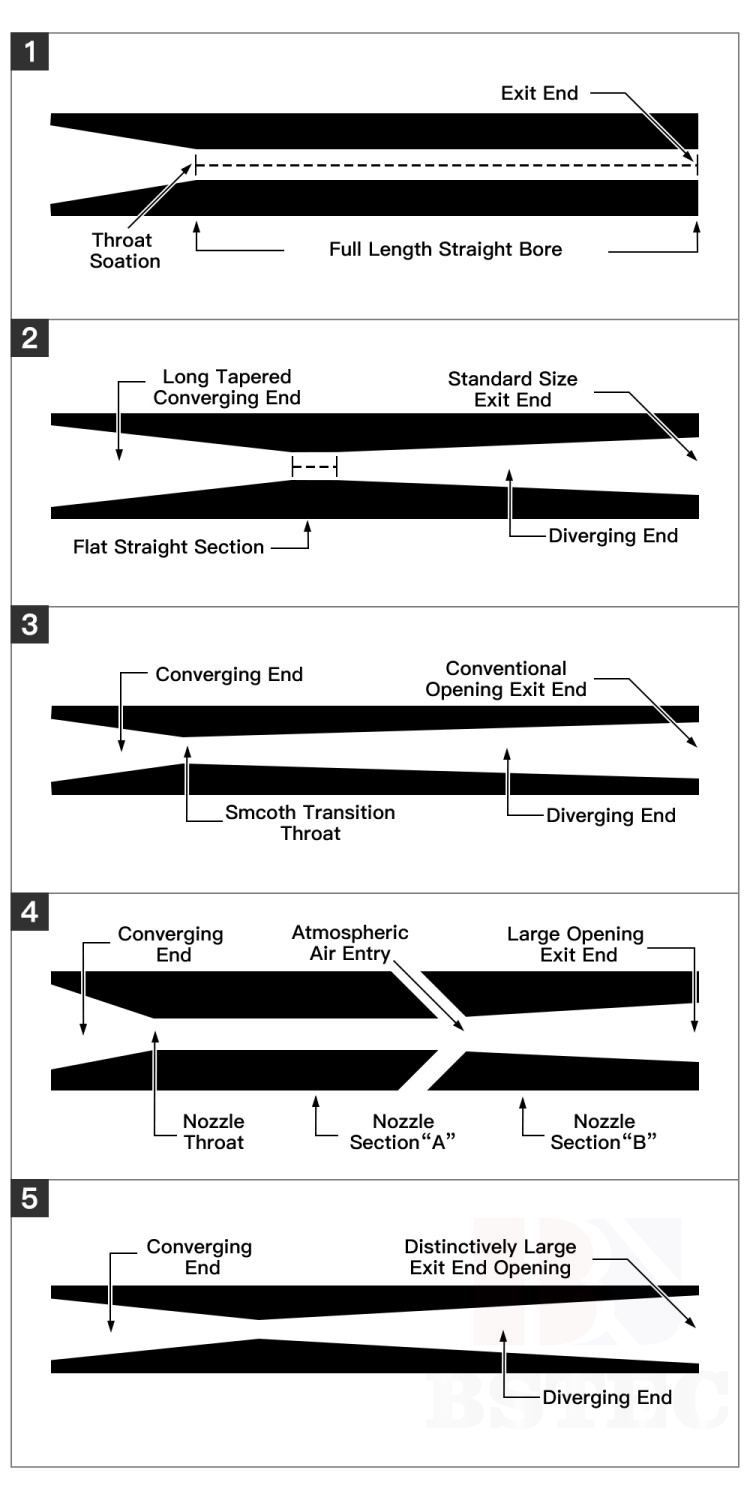

Madaidaicin Bore nozzles(Lamba 1) ƙirƙira ƙaƙƙarfan tsarin fashewa don fashewar tabo ko aikin hukuma. Waɗannan sun fi dacewa don ƙananan ayyuka kamar tsaftace sassa, gyaran gyare-gyaren weld, tsaftace hannaye, matakai, aikin gasa, ko sassaƙan dutse da sauran kayan.

Venturi ya haifar da nozzles(Lambobi 2 da 3) ƙirƙiri faffadan ƙirar fashewa da haɓaka saurin ƙyalli da kusan 100% don matsa lamba.

Venturi nozzles shine mafi kyawun zaɓi don mafi girman yawan aiki yayin fashewar filaye masu girma. Biyu venturi da faffadan nozzles an haɓaka nau'ikan bututun mai na venturi mai tsayi.

Thebiyu venturisalo (Lamba 4) ana iya tunanin shi azaman nozzles guda biyu a jere tare da rata da ramuka a tsakanin don ba da damar shigar da iska a cikin sashin bututun mai. Ƙarshen fitowar kuma ya fi faɗin bututun ƙarfe na al'ada. Dukansu gyare-gyare an yi su ne don ƙara girman ƙirar fashewar da kuma rage asarar saurin ƙyalli.

Fadin nozzles(Lamba 5) yana da babban maƙogwaron shigarwa da babban magudanar ruwa mai nisa. Lokacin da aka dace da tiyo mai girma iri ɗaya za su iya samar da haɓakar 15% na yawan aiki akan nozzles tare da ƙaramin makogwaro. Hakanan yana da kyau a sami nozzles na kusurwa don madaidaicin tabo kamar lattice amarya, a bayan flanges, ko cikin bututu. Yawancin masu aiki suna ɓata abrasives da lokacin jiran ricochet don samun aikin. Ƙananan lokacin da ake ɗauka don canzawa zuwa wanibugun kwanakoyaushe yana dawowa da sauri, kuma jimlar lokacin aikin yana raguwa.

3. Zabi Abun Ciki

Da zarar kun ƙayyade girman bututun ƙarfe da siffar, kuna so kuyi la'akari daabuan yi lilin bututun ƙarfe. Manyan abubuwa guda uku a cikin zaɓin madaidaicin bututun ƙarfe kayan bututun ƙarfe sune karko, juriya mai tasiri, da farashi.

Zaɓin kayan bututun ƙarfe ya dogara da abin ƙura da kuka zaɓa, sau nawa kuke fashewa, girman aikin, da tsananin wurin aiki. Anan akwai jagororin aikace-aikacen gabaɗaya don abubuwa daban-daban.

Tungsten carbide nozzles:Can ba da tsawon rayuwa da tattalin arziki lokacin da ba za a iya guje wa mugun aiki ba. Dace da fashewar slag, gilashin, da abrasives na ma'adinai.

Silicon carbidenozzles:Tasiri mai juriya da dorewa kamar tungsten carbide, amma kusan kashi ɗaya bisa uku na nauyin nozzles na tungsten carbide. Kyakkyawan zaɓi lokacin da masu aiki ke kan aiki na dogon lokaci kuma sun fi son bututun ƙarfe mara nauyi.

Boron carbide nozzles:Mai matuƙar wuya kuma mai ɗorewa, amma gaggautsa. Boron carbide yana da kyau don abrasives masu tayar da hankali kamar aluminum oxide da zaɓaɓɓun tarukan ma'adinai lokacin da za'a iya guje wa mugun aiki. Boron carbide zai yawanci fitar da tungsten carbide da sau biyar zuwa goma sannan kuma silicon carbide sau biyu zuwa uku lokacin da ake amfani da abrasives masu tayar da hankali. Farashin kuma shine mafi girma a cikinsu.

4. Zabi Zaren da Jaket

A ƙarshe, kuna buƙatar zaɓar kayan jaket ɗin da ke kare ɓarna. Hakanan kuna buƙatar yin la'akari da irin salon zaren da ya fi dacewa da buƙatun yashi: zare mai kyau ko kuma zaren ɗan kwangila.

1) Nozzle Jacket

Aluminum Jaket:Jaket ɗin aluminum suna ba da babban matakin kariya daga lalacewar tasiri a cikin nauyi.

Jaket ɗin Karfe:Jaket ɗin ƙarfe suna ba da babban matakin kariya daga lalacewar tasiri a cikin nauyi mai nauyi.

Jaket ɗin roba:Jaket ɗin roba yana da nauyi yayin da yake ba da kariya ta tasiri.

2) Nau'in Zare

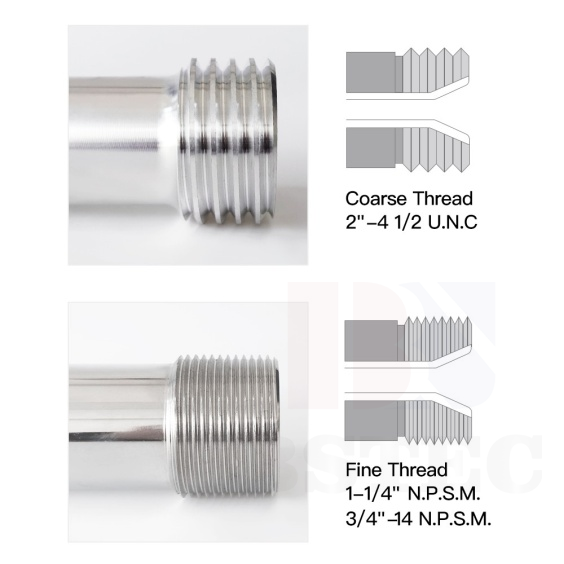

Matsakaicin (Dan kwangila) Zaren

Madaidaicin zaren masana'antu a zaren 4½ a kowane inch (TPI) (114mm), wannan salon yana rage damar yin zaren giciye kuma yana da sauƙin shigarwa.

Fitaccen Zaren(Tsarin NPSM)

Matsakaicin ƙa'idar ƙasa kyauta madaidaiciya ita madaidaiciya ita ce (NPSM) ita ce masana'antar daidaitaccen tsarin da aka yi amfani da ita sosai a Arewacin Amurka.

TUNANIN KARSHE

Babban iska da manyan nozzles suna haifar da ƙimar ƙima mai girma, amma sifar bututun ƙarfe ne ke ƙayyade hanzarin barbashi da girman ƙirar fashewar.

Gabaɗaya, babu mafi kyawun bututun ƙarfe, babban mahimmin shine nemo mafi kyawun nozzles don amfanin ku.