10 Questions to Ask Your Replacement Air Filter Cartridge Supplier

10 Questions to Ask Your Replacement Air Filter Cartridge Supplier

Choosing a supplier for your breathing air filter cartridges? Ask these 10 critical questions about quality, compliance, and compatibility to ensure worker safety and avoid costly mistakes. Read now.

Procuring replacement air filter cartridges for your sandblasting operations is a decision that carries significant weight. The right supplier safeguards your workers' health, ensures regulatory compliance, and protects your bottom line. The wrong one can lead to catastrophic failures, costly downtime, and severe liability. To navigate this critical choice, you need to be armed with the right questions. This list of 10 essential queries will help you cut through the marketing speak and identify a truly reliable partner who understands the severe demands of the abrasive blasting industry.

1. Can You Provide Documentation of OSHA Grade D Compliance?

This is the non-negotiable starting point. Any supplier must provide test reports or certificates proving their cartridges produce air that meets OSHA 29 CFR 1910.134 Appendix D standards. This isn't just about efficiency; it's about legal compliance. Without this documentation, you are assuming immense risk. A reputable supplier will have this data readily available and transparent.

2. What is the Exact Composition and Design of Your Cartridge?

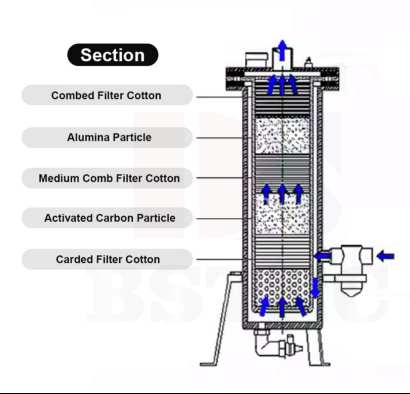

Don't settle for vague answers like "activated carbon." Drill down. What is the type and grade of carbon? What is its iodine value (a measure of adsorption capacity)? What is the density and composition of the pre-filter coalescing media? A technical breakdown shows expertise and confidence in their product's construction.

3. Are Your Cartridges Compatible with [Insert Your Filter Housing Brand]?

Specify your equipment brands, such as Clemco, Bullard, Twin Air, or Marco. A perfect, leak-free seal is critical. The supplier should guarantee compatibility and ideally have dimensional drawings or compatibility charts to prove it. Incompatibility can render even the best cartridge ineffective.

4. What is Your Typical Lead Time for Bulk Orders?

Consistent supply is vital for operational continuity. Unreliable lead times can force premature cartridge changes or, worse, complete work stoppages. A professional supplier will have a robust supply chain and provide realistic, dependable lead times, even for large orders

5. Do You Offer Technical Support and Expertise?

When you have a question about performance, replacement schedules, or troubleshooting, can you speak to an engineer or a sandblasting safety specialist? Or are you passed to a general customer service agent? Access to expert advice is a hallmark of a value-added supplier.

当

Questions 6-10 would continue in a similar detailed format, covering:

6. What Quality Control Measures are in Place During Manufacturing?

7. Can You Provide References from Other Sandblasting Companies?

8. How Do You Handle Issues with Defective or Underperforming Batches?

9. What is Your Policy on Minimum Order Quantities (MOQs) and Sample Availability?

10. Beyond Price, What Differentiates You from Other Suppliers?

Asking these detailed, pointed questions transforms you from a passive price-shopper into an informed, value-driven buyer. The answers you receive will clearly separate the true partners from the mere order-takers. For a supplier that welcomes these questions and provides satisfactory, expert answers, look to BSTEC®. We are prepared to demonstrate our commitment to quality, safety, and performance.