Cost-Effective vs. Premium Sandblasting Nozzles: Which One Saves You More

Cost-Effective vs. Premium Sandblasting Nozzles: Which One Saves You More?

Introduction: The True Cost of Sandblasting Nozzles

In surface preparation and coating operations, sandblasting nozzles represent one of the most frequently replaced - yet critically important - components. While budget nozzles may appear attractive for their low upfront costs, our comprehensive analysis reveals why premium nozzles often deliver superior long-term value. This 1,200-word guide examines five key financial and operational factors to help you make the most cost-effective choice for your business.

1. Initial Investment vs. Operational Lifespan

The purchase price difference between nozzle types tells only part of the story:

Cost and Durability Comparison:

Nozzle Type | Price Range | Average Lifespan | Cost per 1,000 Hours |

Steel | $10-$20 | 10-20 hours | $500-$1,000 |

Ceramic | $30-$50 | 100-200 hours | $150-$300 |

Tungsten Carbide | $80-$200 | 500-1,000 hours | $80-$200 |

Boron Carbide | $200-$400 | 800-1,500 hours | $130-$250 |

Technical Insight: Tungsten carbide's exceptional wear resistance comes from its unique composite microstructure - hard tungsten carbide particles embedded in a tough cobalt matrix. This combination provides both hardness (2,600 HV) and fracture resistance.

2. Productivity and Blasting Efficiency

Nozzle quality directly impacts job completion times and surface finish quality:

Performance Metrics:

✅Cutting Speed: Premium venturi nozzles achieve 30-40% faster cleaning rates

✅Surface Profile Consistency: Worn nozzles create uneven surface textures (Ra variance up to 50%)

✅Operator Fatigue: Lightweight premium nozzles reduce fatigue during extended use

Case Study: A pipeline coating company reduced blasting time from 8 hours to 5 hours per section after switching to tungsten carbide venturi nozzles, while achieving more consistent surface profiles.

3. Abrasive Media Consumption

Nozzle wear dramatically increases media costs:

Media Waste Analysis:

Nozzle Condition | Bore Increase | Media Waste Increase | Additional Cost per Ton |

New | 0% | Baseline | - |

10% Worn | +0.5mm | 15-20% | $40-$60 |

20% Worn | +1.0mm | 30-40% | $80-$120 |

Pro Tip: Regular bore measurements with plug gauges can alert you to excessive wear before media waste becomes significant.

4. Labor and Downtime Considerations

Frequent nozzle changes create hidden costs:

Operational Impact:

Nozzle Change Time: 10-15 minutes per change (including system depressurization)

Annual Labor Cost:

Steel nozzles: 250+ changes/year = 40-60 labor hours

Tungsten carbide: 2-4 changes/year = <1 labor hour

Real-World Example: A shipyard employing 10 blasting crews saved over $35,000 annually in labor costs after switching to premium nozzles.

5. Total Cost of Ownership Analysis

A comprehensive 1-year comparison reveals the true savings:

TCO Breakdown (Per Nozzle Position):

Cost Factor | Steel Nozzle | Tungsten Carbide |

Nozzle Purchases | $500 | $200 |

Abrasive Waste | $1,200 | $400 |

Labor for Changes | $900 | $50 |

Downtime Impact | $1,500 | $100 |

Total Annual Cost | $4,100 | $750 |

When Budget Nozzles Make Sense

While premium nozzles typically offer better value, economical options have valid applications:

Appropriate Uses for Budget Nozzles:

1. Occasional hobby or craft projects

2. Very soft media (plastic beads, baking soda)

3. Extremely low-budget temporary operations

4. Training situations where damage is likely

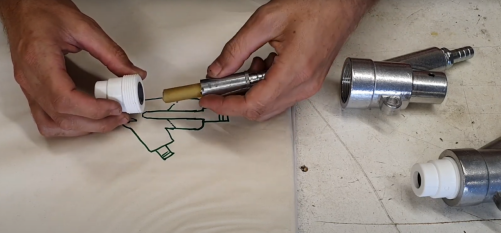

Maintenance Tips to Maximize Value

Proper care extends nozzle life regardless of type:

Best Practices:

1. Daily bore diameter checks with go/no-go gauges

2. Proper storage in padded, dry containers

3. Regular cleaning with nylon brushes (never metal)

4. Consistent air pressure maintenance

5. Operator training on proper handling techniques

Conclusion: Making the Smart Investment

For most industrial operations processing hard abrasives, premium tungsten carbide nozzles deliver:

60-80% lower total operating costs

25-40% productivity improvements

More consistent surface preparation quality

Reduced downtime and labor requirements

We recommend conducting a 30-day trial comparing your current setup with premium nozzles - most operations achieve payback within 3-6 months.